Why It Matters and How to Do It Right

Let’s be honest if you’ve worked anywhere near a marine boiler, you’ve heard the term “blowdown.” And if you’ve ever seen dirty boiler water or sludge at the bottom of the gauge glass, you already know why it matters.

Think of blowdown as giving your boiler a regular clean up. It’s simple, but it’s one of the most important things you can do to keep the system healthy and safe. So, let’s break it down into plain English: what blowdown actually is, why it’s so important, and how to do it without messing things up.

So, What’s Boiler Blowdown Anyway?

Over time, as the boiler runs, steam leaves the system nice and clean. But everything that doesn’t turn into steam (sludge, salts, oils, dirt, chemicals) stays behind. That stuff just keeps building up in the water unless you remove it.

Blowdown is just opening specific valves to get rid of that dirty water, before it causes problems like:

- Corrosion

- Scale on the tubes

- Overheating

- Poor steam quality

- Boiler damage

Do it regularly, and your boiler stays happy. Skip it for too long? Well, you’ll be doing a lot more than just draining water.

Types of Blowdowns You’ll See Onboard

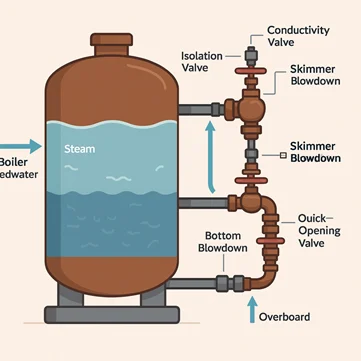

1. Bottom Blowdown

This is the heavy-duty one. It clears out sludge and other solid stuff that settles right at the bottom of the boiler.

It’s usually done manually and only for a few seconds at a time. Quick and dirty but necessary.

2. Skimmer (or Surface) Blowdown

This one’s more precise. It targets lighter stuff like oil, foam, and dissolved solids that float near the top.

Usually done automatically using a conductivity meter, and it helps control TDS (Total Dissolved Solids).

Why You Should Care About Blowdown

Think of it like changing the oil in your engine if you don’t, things get messy fast. Here’s what proper blowdown helps with:

- Stops corrosion and scaling

- Keeps heat transfer efficient

- Prevents overheating and tube failure

- Improves steam quality

- Keeps the boiler running safely and reliably

Basically, it saves you from major headaches (and possibly major breakdowns)

How to Do a Bottom Blowdown – Step-by-Step

Let’s keep this practical. Here’s how you normally do a bottom blowdown onboard:

- Make sure the boiler isn’t under heavy load. Best to do it during low load or standby.

- Double-check the water level and make sure all safety procedures are in place.

- Start with both blowdown valves closed quick-opening and slow-opening.

- Open the overboard valve (you don’t want that sludge going into the bilge).

- Open the quick-opening valve all the way.

- Crack open the slow-opening valve slowly you’ll hear it roar. That’s the junk getting flushed out.

- Watch the gauge glass and blow down for maybe 30–60 seconds, depending on how dirty it is.

- Close the slow-opening valve first.

- Open and close it again a few times helps stir up the sludge and push it out.

- Then close the quick-opening valve.

- Finally, quickly open and shut the slow valve again to drain any leftover water.

- Make sure both valves are fully closed and no leaks are left behind.

Skimmer Blowdown – The Smoother Option

If your boiler has a skimmer setup, here’s what you need to know:

- Use a conductivity meter to monitor how dirty the water is.

- Adjust the needle valve or flow control to keep the rate in check.

- Make sure water is being drawn from just below the surface.

- Stick to the TDS limits recommended by your water treatment provider.

- If you have an automatic blowdown system, let it do the work just keep an eye on it.

How Often Should You Blow Down?

This depends on your ship’s operations and water quality, but here’s a general guide:

- Bottom blowdown: Once per watch or daily (depends on how bad the water is).

- Skimmer blowdown: Can be done continuously if automated, or a few times a day if manual.

- Weekly routines: Blow down your sight glass, safety valves, and level switches to keep them clean and working.

Do It Right – Do It Responsibly

A couple of reminders to stay compliant and protect the environment:

- Never blow down in port or near ecologically sensitive areas.

- If you suspect oil contamination, don’t blow down — report it and isolate the source.

- Follow all environmental rules like VGP and MARPOL.

- Log every blowdown in the engine room logbook.

Pro Tips from the Real World

- Use high-quality feedwater to reduce the need for heavy blowdowns.

- If you can, recover heat from blowdown water using a heat recovery system — saves energy.

- Don’t blow down too much — you’ll just waste energy and water. Find the balance.

- If you’re not sure, ask a senior before doing it. Better safe than sorry.

Final Thoughts

Blowdown might seem like a small job, but it plays a massive role in your boiler’s health and your ship’s safety. It only takes a minute or two, but it prevents expensive repairs, improves efficiency, and keeps you out of trouble.

Take it seriously. Do it regularly. And most importantly, do it the right way.