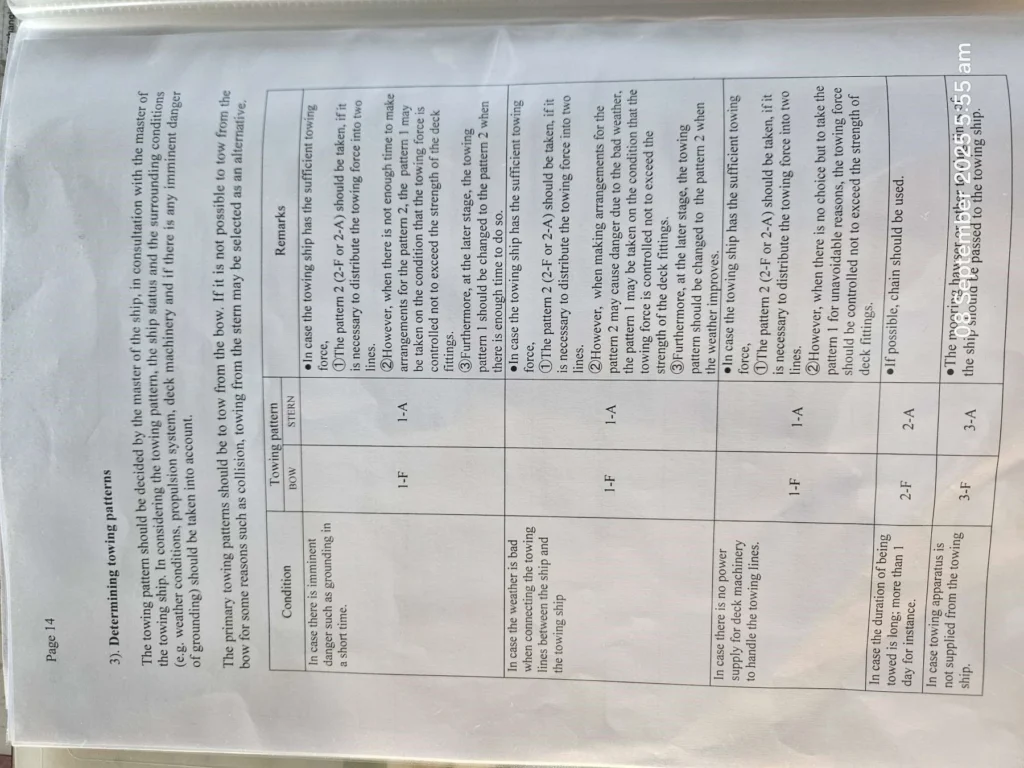

The Emergency Towing Booklet (ETB) is a mandatory, ship-specific manual which describes how a vessel can safely be towed from both forward and aft in case of a breakdown, collision, or loss of manoeuvrability.

It is not just a “theoretical” booklet; it should be a practical guide for the crew during an actual emergency.

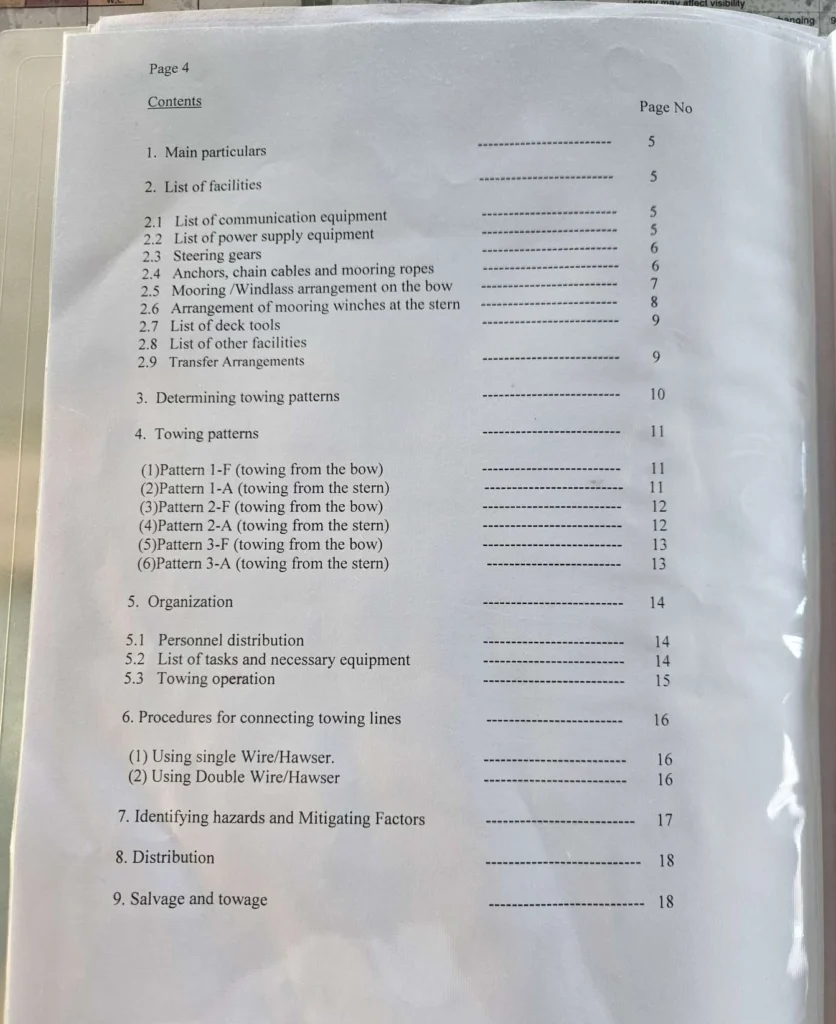

The typical contents of an ETB include:

- General Information

Ship particulars (LOA, beam, draft, DWT, bollard pull requirement).

Reference to SOLAS Ch. II-1 Reg. 3-4 and IMO Guidelines MSC.1/Circ.1255.

The purpose of this action is to ensure rapid, safe, and effective connections with tugs.

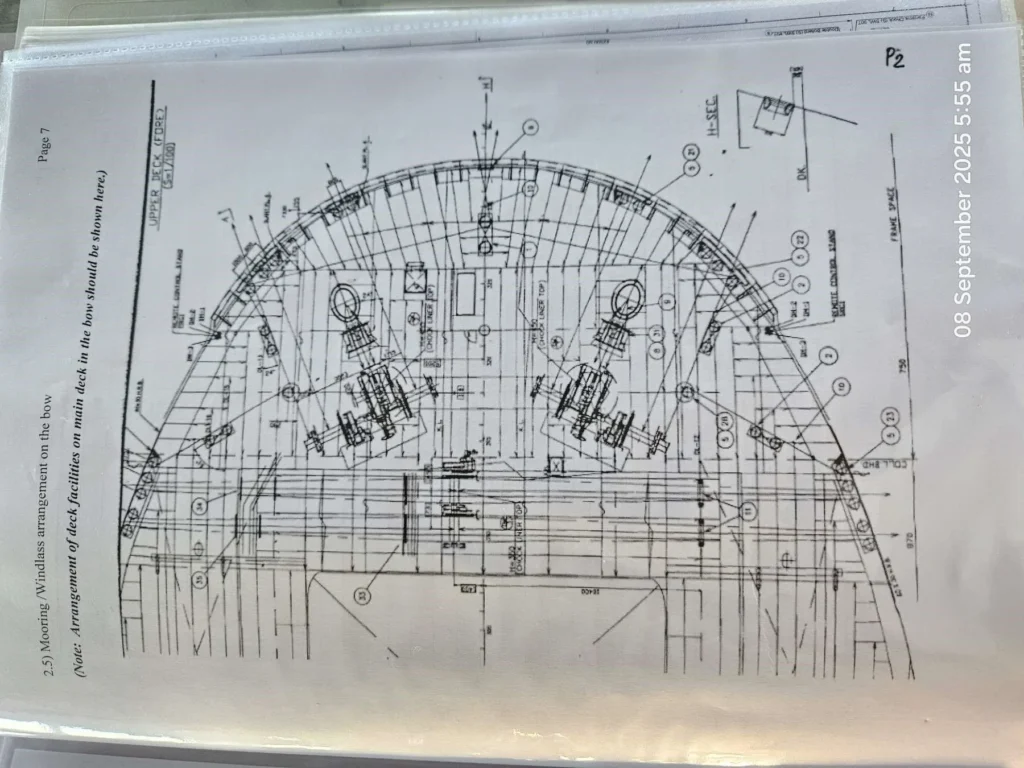

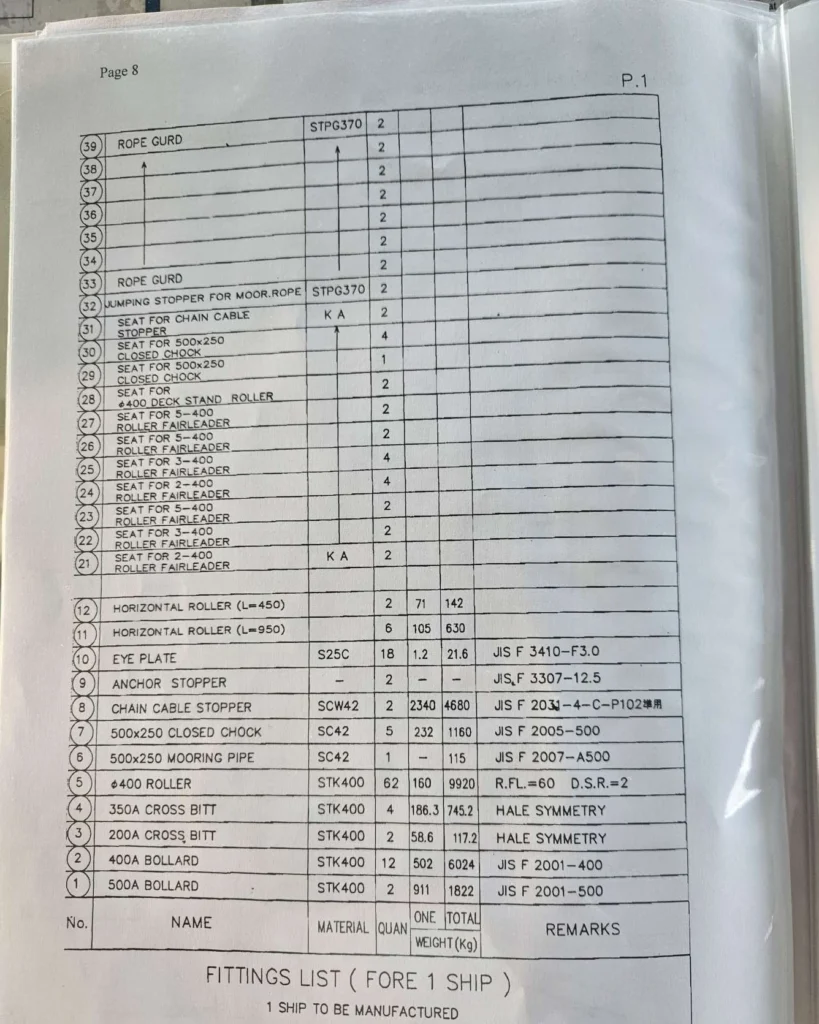

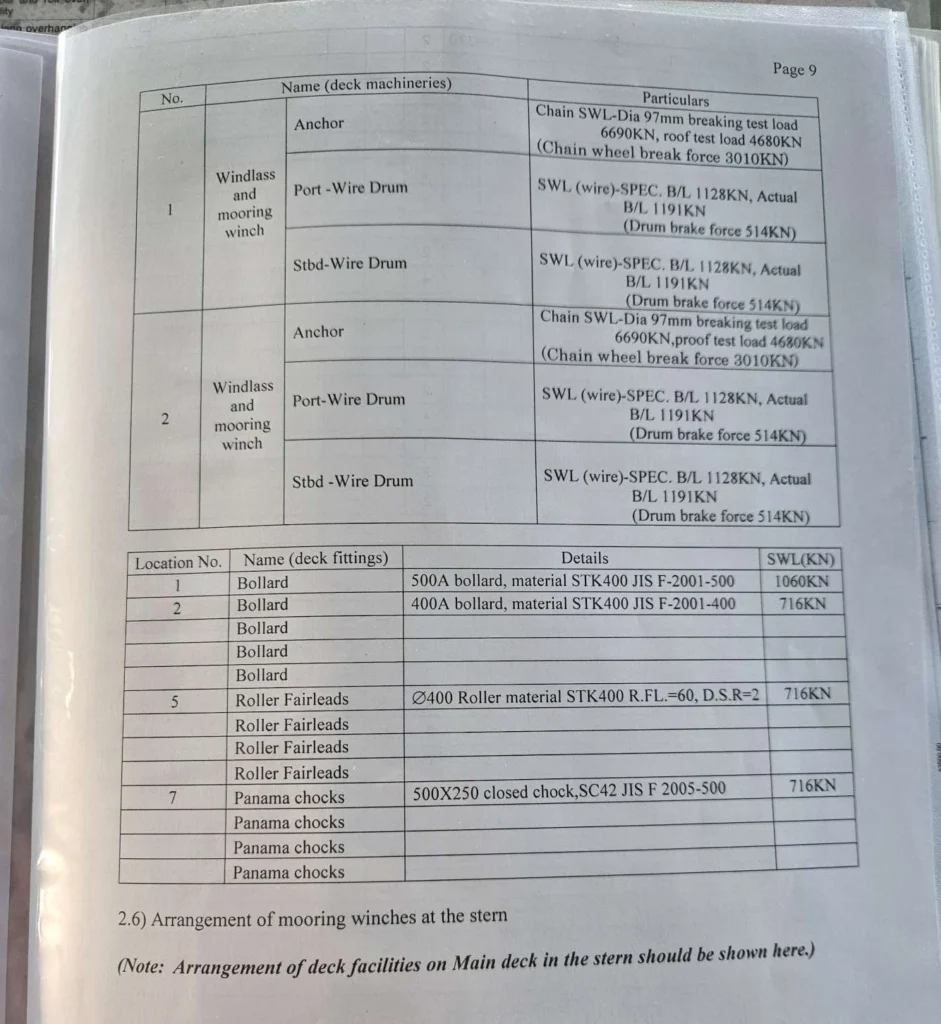

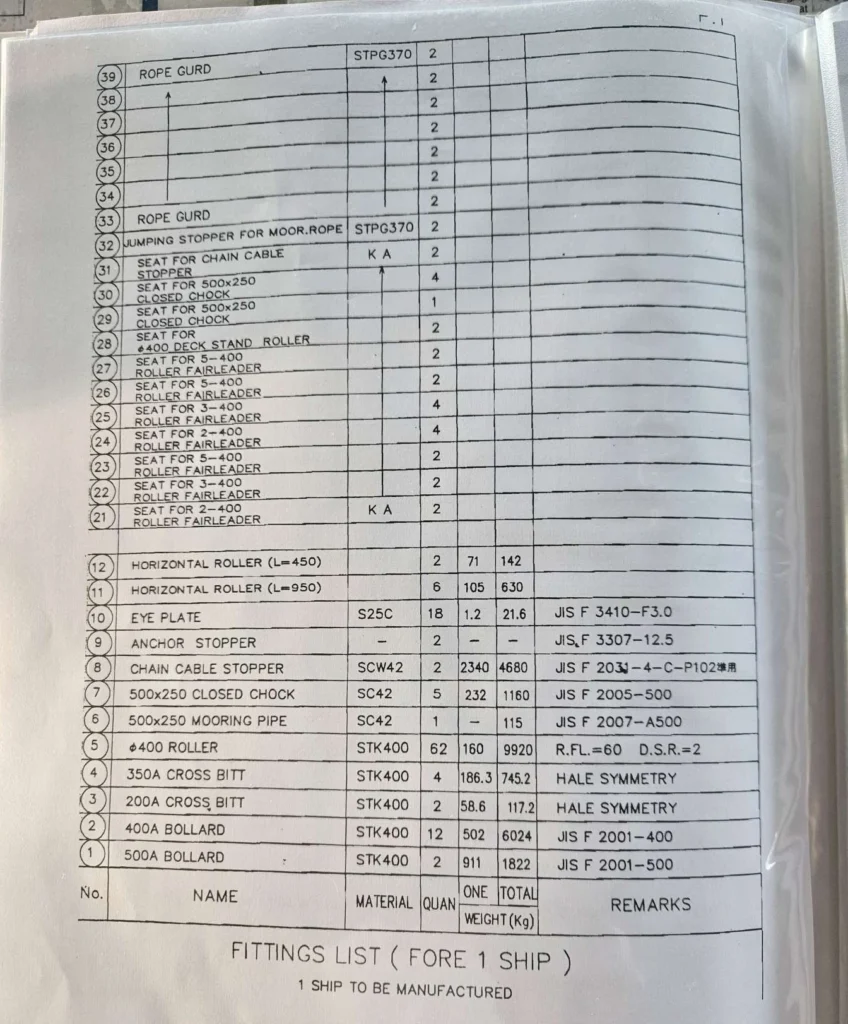

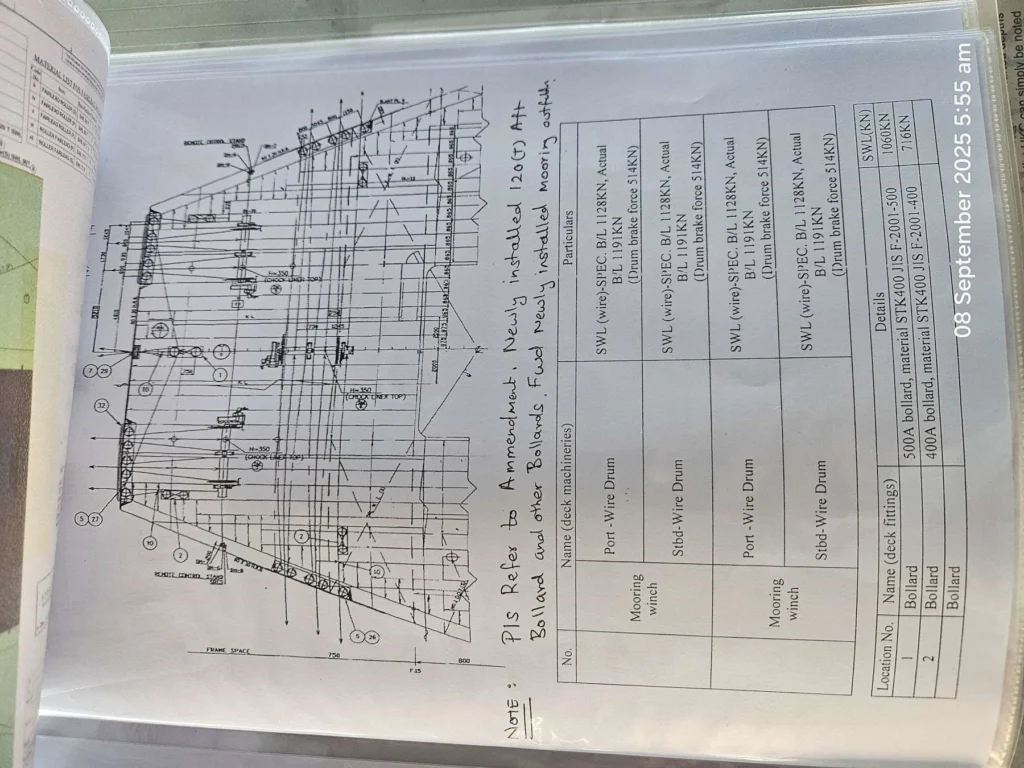

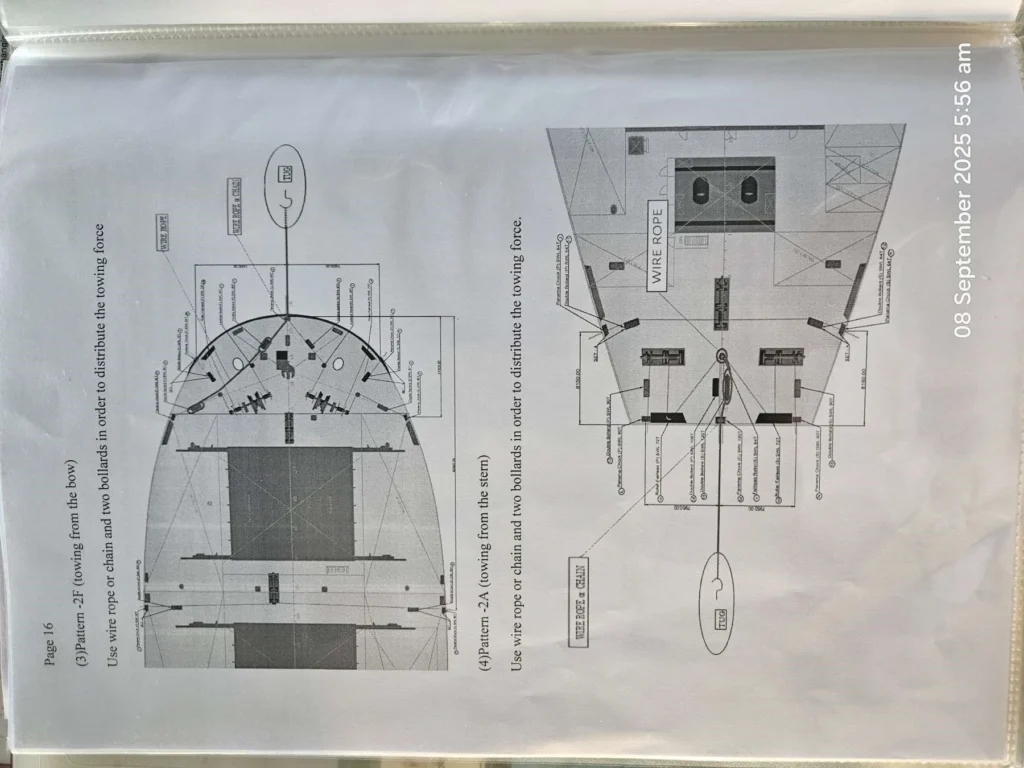

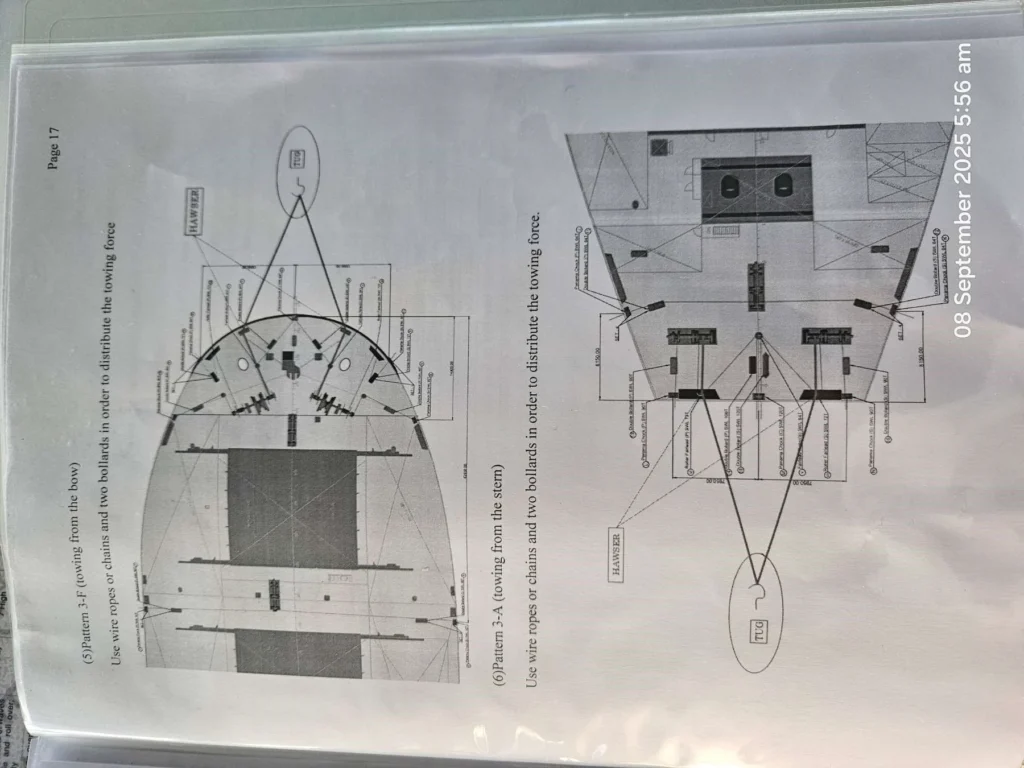

- Towing Arrangement – Forward & Aft

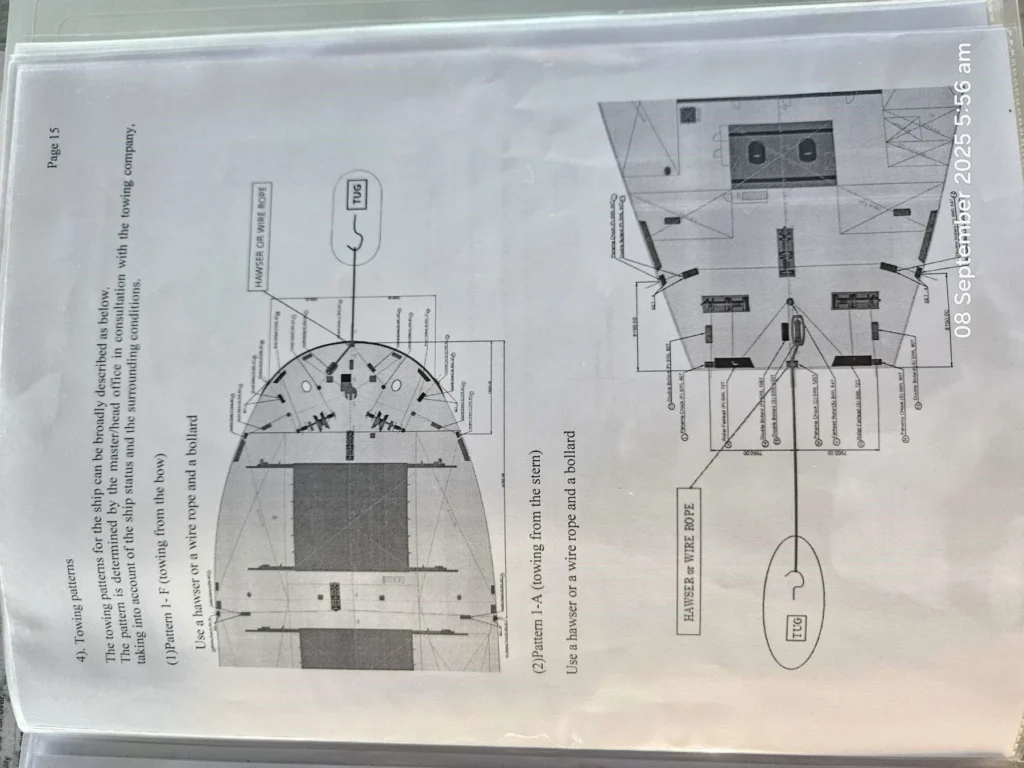

Diagrams/plans indicating the location of towing leads, strong points, bollards, fairleads and chocks.

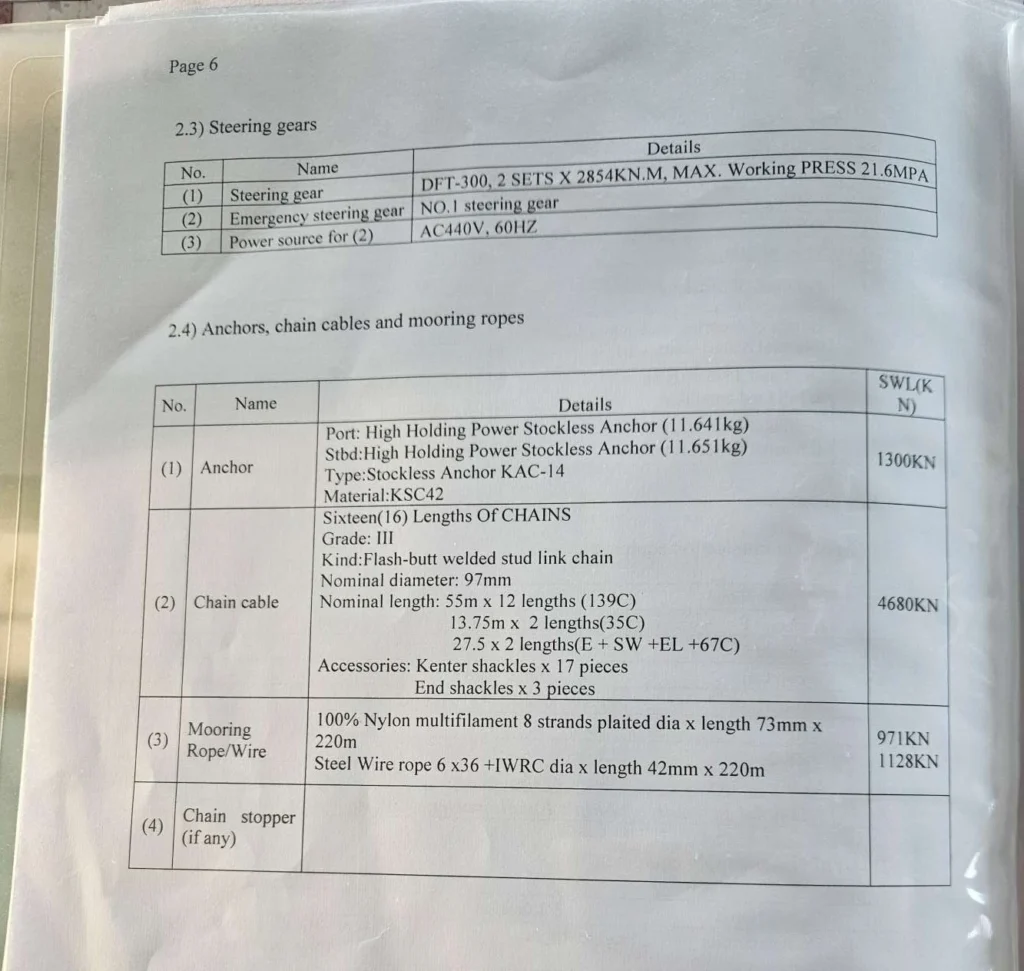

Marked safe working loads (SWL) of fittings.

Designated strong points for towing gear.

Clear lead arrows showing the wires/ropes should be led to avoid sharpe angles that could cause damage.

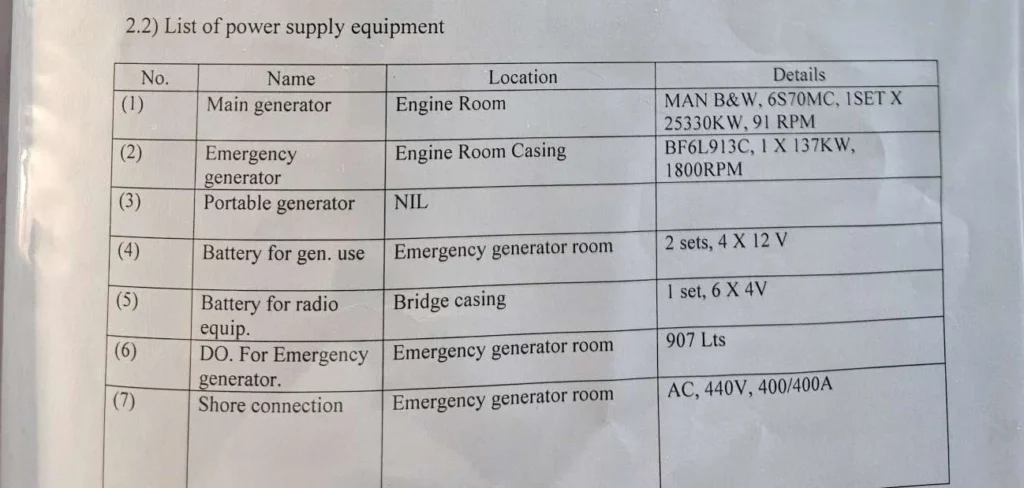

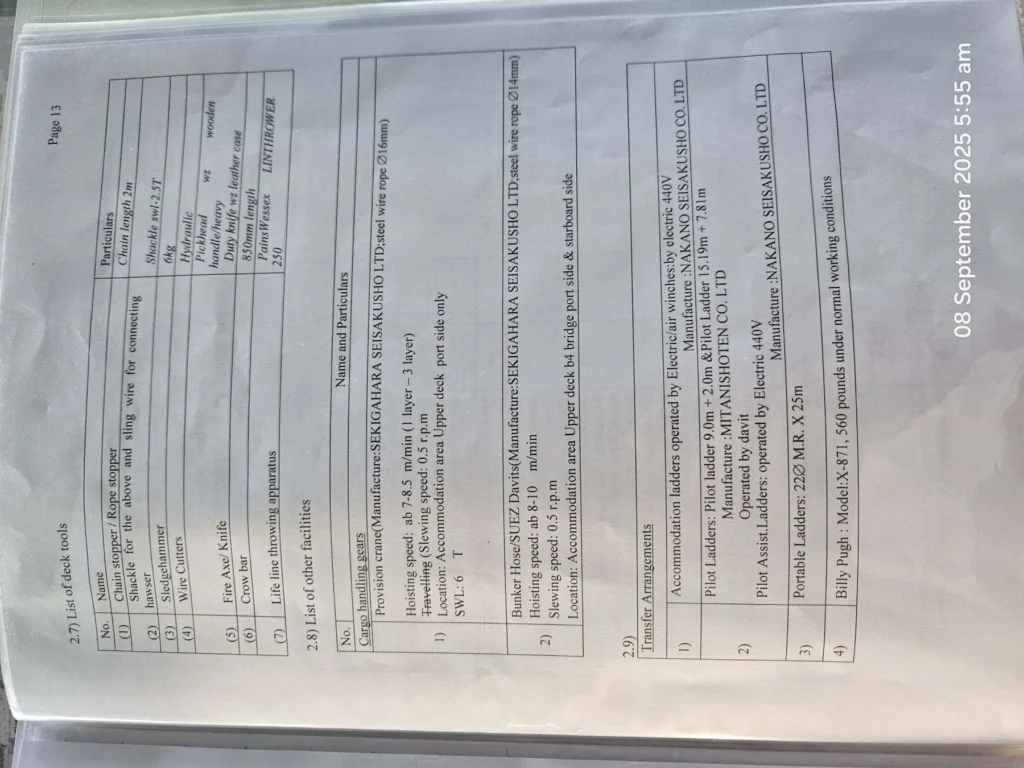

- Towing Equipment Available Onboard

Emergency towing wires (location, length, diameter, breaking strength).

Strong shackles, chain stoppers and messenger ropes.

Heaving lines and winches to assist in passing the towing line.

Portable fairleads (where applicable).

Details of emergency towing gear stored forward and aft.

- Deployment Procedures

Step-by-step guidance such as:

Who is in charge – usually Chief Officer forward, 2/O aft, under Master’s command

How to remove and prepare wires/shackles safely.

Throwing a heaving line to tug, then messenger, then main towing wire.

Securing towing wire to ship’s strong point.

Safety checks before taking the load: crew must stand clear, winch brakes tested.

Communication methods with the tug and bridge.

- Crew Responsibilities

Master: overall command and communication with tug.

Chief Officer: supervise rigging forward.

Second Officer: supervise rigging aft.

Bosun & ABs: tend messenger lines, shackles, wires.

Engineers: ensure power available for winches if required.

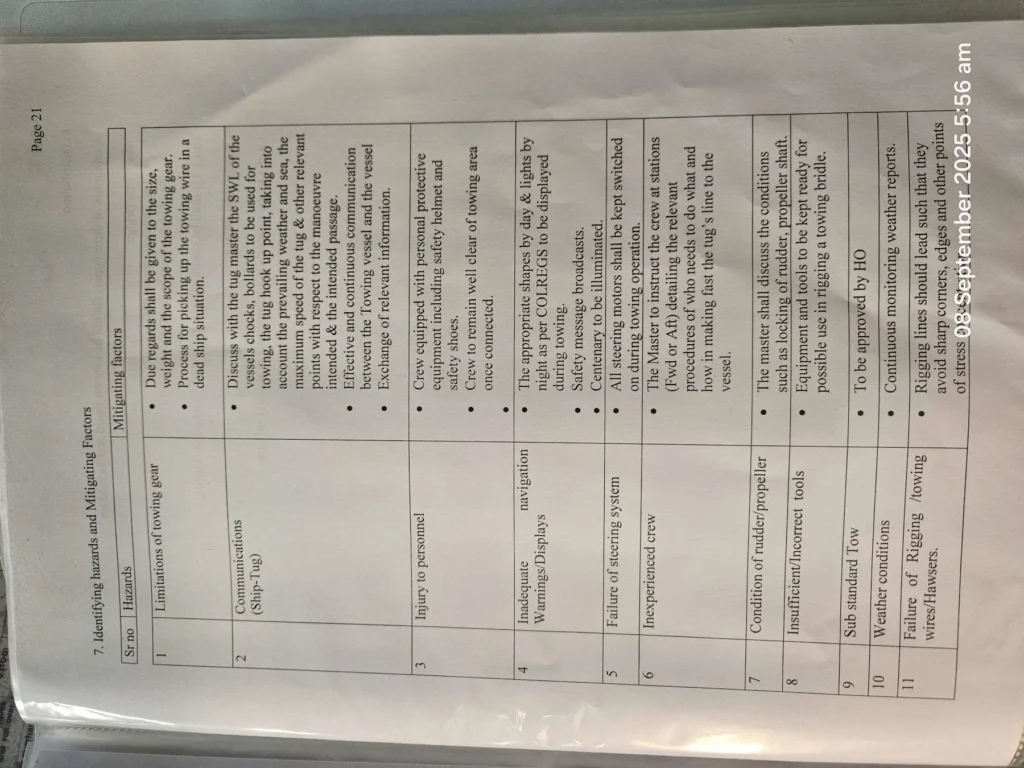

- Safety Precautions

Crew to remain clear of snapback zones.

PPE requirements: helmets, gloves, lifejackets.

Avoid sharp leads that may potentially damage wires.

Never exceed SWL of fittings.

Emergency stop signals for winches.

- Maintenance & Inspection

Periodic examination of chocks, bitts, fairleads (greasing, free movement).

Check the condition of wires and shackles.

ETB updated after dry-dock modifications.

Record of crew drills related to emergency towing.

- Plans & Drawings (Mandatory)

Clear scaled drawings showing both fore and aft towing arrangements.

Strong points highlighted with SWLs.

Lead diagrams showing how tugs should connect

Emergency contact numbers of company, salvage tugs, etc. – optional

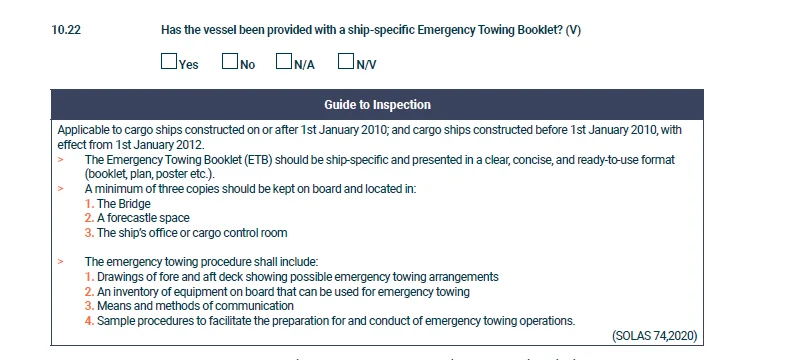

How ETB is checked during RightShip and 3rd party inspections

Inspectors from RightShip generally check the following:

Availability: Is the ETB on board and accessible on the bridge/ECR?

Specificity: Is it specific to ship instead of a generic template?

Drawings: Do the towing diagrams make sense?

Crew Familiarity: Can the officers explain and point to the towing points on-deck?

Condition of the Equipment: Are the fittings maintained and not corroded?

Updates: Has the booklet been revised following any modifications/dry-dock?

Training Records: Has the drills or toolbox talks relating to emergency towing been recorded?

If any of this is not in place, this may result in an observation such as:

> Emergency Towing Booklet not ship specific/ crew not familiar with towing arrangement.

Why This is Important for Bulk Carriers

Bulk carriers are different from smaller vessels, bulk carriers:

Require strong bollard pull tugs in an emergency.

Take more time to respond in congested waters. Thus, a clear and updated ETB is crucial-it avoids delay, confusion, and accidents during emergence situations. Below are a few photos from an actual emergency towing booklet onboard.