A Lifesaving System Every Officer Must Understand

On a bulk carrier, the biggest threat is not always fire or collision. Sometimes, danger creeps in silently, below the cargo, in the form of water entering where it should never be. That is where the Water Ingress Alarm Panel comes into play. It is a quiet sentinel standing guard round the clock, watching for signs of flooding in the most vulnerable areas of the ship.

Let us understand this system properly.

What is the Water Ingress Alarm Panel

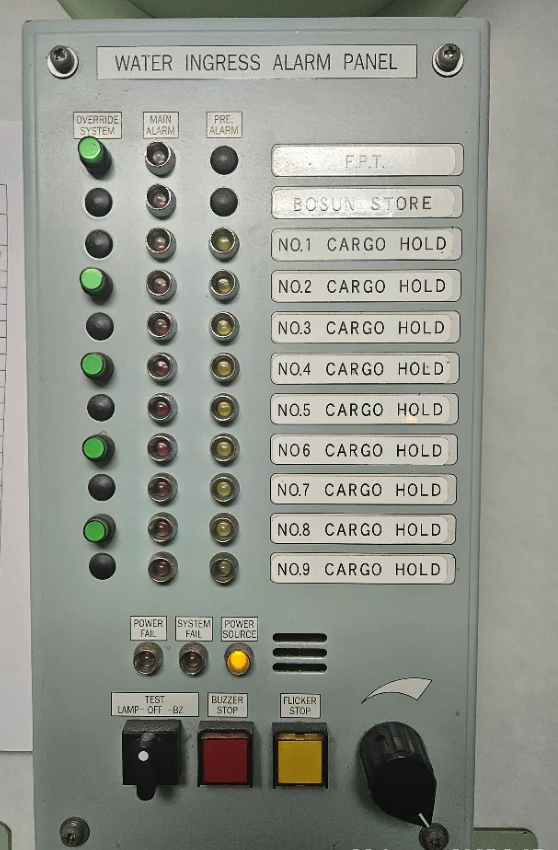

The Water Ingress Alarm Panel is a specialized monitoring system positioned on the bridge that will detect and notify the duty officer about water entering specific compartments in the vessel. This panel, on a bulk carrier, is particularly important due to the cargo hold arrangements and double bottom tanks.

Typically, this panel is linked to sensors located in specific spaces, mainly the forward cargo holds, forepeak tank and other susceptible spaces. When water reaches a predetermined level in those spaces it will activate the sensor which in turn sends a signal to the panel for a designated alarm to sound.

Why It Is So Important on a Bulk Carrier

Bulk carriers often have long, open cargo holds. If water seeps into these holds due to hull damage, cracked bilges, or heavy weather, it can cause cargo shift, loss of stability, and even sinking.

Some of the most tragic bulk carrier incidents in maritime history were caused by unnoticed water ingress. This is why IMO made it mandatory under SOLAS for certain bulk carriers to be fitted with water ingress detection systems.

Areas Monitored by Water Ingress Alarms

On most bulk carriers, the following compartments are monitored

- Forepeak tank

- Cargo holds

- Any dry spaces forward of cargo holds

- Double bottom tanks if fitted with sensors

- Any forward pipe tunnels

What You Should Check as an Officer

When you come on bridge watch or carry out your weekly bridge checks, do not skip the water ingress alarm panel. Here is what you should look for

- Power Supply

Make sure the panel has power and is online. Any fault lights or power failure indicators must be investigated.

- Visual Indicators

Ensure that all zones are showing normal status. No false alarms, no sensor faults, and no bypassed zones unless under maintenance.

- Alarm Function Test

Some panels have a self-test button. If your company PMS or checklists require it, carry out a test and log it properly.

- Log Entries

Always record any alarm triggered, even if it was a test or false alarm. Mention the time, zone, cause, and action taken.

What to Do If an Alarm Sounds

Stay calm but act quickly.

Check the panel display to identify the affected area

Inform the Master immediately

Call the duty engineer and ballast control

Sound the general alarm if required

Activate bilge pumping arrangements if flooding is confirmed

Monitor the water level continuously

Prepare to abandon ship if the situation worsens

Common Defects and Mistakes

Faulty or corroded sensors in cargo holds

Panel left unpowered during maintenance

Lack of regular testing

No entries in bridge log when alarms go off

Officers ignoring brief false alarms

Final Thoughts

The water ingress alarm panel may not be as eye-catching as radar or ECDIS, but it can mean the difference between rescue and tragedy in an emergency. As an officer, you should not regard any other safety equipment on the bridge as less important.

Always test it, and understand it, and respect it.

Stay alert. Stay dry. Stay safe.

Written by a seafarer, for every seafarer out there.

Sample photo of a water ingress panel on the bridge of a bulk carrier having 9 cargo holds