Learn about the significance of tightness tests during dry-docking and repairs. Discover how shipyard inspections protect against the risk of leaks, promote safety and prolonging the life of your vessel.

Introduction

Loose water-test is one of the most essential jobs performed when a ship enters into dry dock. This inspection might seem a bit ho-hum, but it’s pivotal in the ship’s safety, efficiency and long-term performance. Whether it is with water ballast tanks, fuel oil tanks or heating coil tests, the intent is simple: to ensure there are no leaks.

A tightness test POP report was prepared recently during a vsl’s dry docking at Yiulian Dockyard (Zhoushan) Ltd. Let’s unpack what that means, why it matters and how seafarers should think about it.

What is a Tightness Test?

A tightness test is an inspection method used to check whether tanks, pipelines, and heating coils are free from leaks after maintenance or repairs. It is usually carried out using air pressure or hydrostatic testing.

Air Test: Pressurizing the space with air and checking for leaks with soap solution or gauges.

Hydrostatic Test: Filling with water and monitoring pressure changes.

For safety reasons, air tests are common in shipyards, especially for tanks and heating coils.

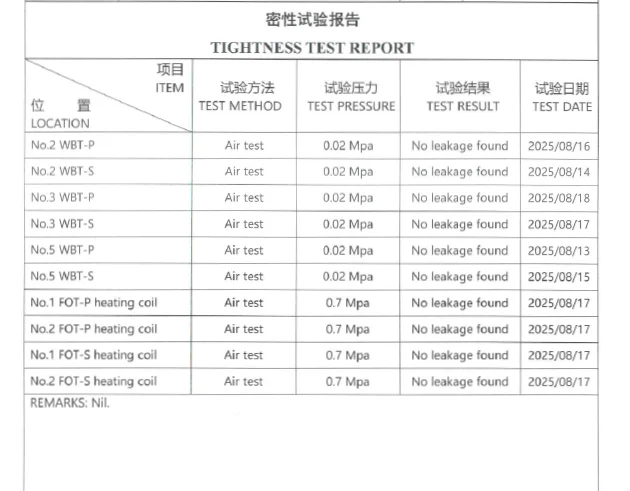

Example: A Screenshot of a Tightness Test Report of a vsl at dry dock is shown below

The inspection report included the following highlights:

Tanks Tested: No.2, 3, 5 Water Ballast Tanks (WBT) – both Port & Starboard

Method: Air test

Test Pressure: 0.02 MPa for tanks, 0.7 MPa for fuel oil tank heating coils

Result: No leakage found

Dates: August 2025

This means all tested compartments and heating coils passed the inspection successfully.

Why Tightness Testing is Critical

- Safety of the Ship

Any leakage from ballast tanks into cargo holds or fuel tanks into the sea can cause serious safety hazards.

- Environmental Protection

Fuel oil leaks are a major environmental concern and can lead to penalties, detentions, and reputational damage.

- Compliance with Class & Regulations

Classification societies and IMO regulations mandate tightness checks during surveys and dry docking.

- Preventing Costly Repairs Later

Detecting small leaks during dry dock prevents major failures during voyage.

The Procedure in Practice

During an air tightness test, here’s how it typically works:

- Preparation: All manholes and valves are sealed.

- Pressurization: The tank or coil is pressurized with air at a set test pressure.

- Monitoring: The pressure is held for a specified duration.

- Leak Detection: Soap water solution is applied to joints, weld seams, and fittings to check for air bubbles.

- Recording: Inspector notes down the pressure, time, results, and date in the official test report.

Lessons for Seafarers

As a cadet or junior officer, here’s what you should learn from tightness testing:

Never underestimate “No leakage found.” It means your ship is structurally sound and safe to operate.

Get familiar with test pressures. For ballast tanks it’s usually 0.02 MPa, for heating coils higher, around 0.7 MPa.

Always monitor during re-commissioning. Even after successful tests, keep an eye when tanks are first filled after dry dock.

Understand the documentation. Tightness test reports are vital records for Class, PSC, and RightShip inspections.

Pro Tip from a Ship Captain

If you are onboard after dry dock, personally check the tanks and coils when they are first put back in use. Even a passed report doesn’t replace your own inspection. Look for seepages, monitor tank sounding levels, and ensure bilges are dry. This proactive habit can save your vessel from unnecessary trouble.

Conclusion

Tightness testing would seem a banal entry in the inspection report but is one of the most important activities on dry docking. It makes certain that your ship’s tanks and systems are tight, COFR compliant and prepared for safe operation at sea.

This knowledge about such reports and their impact is invaluable to any mariner so as to have confidence and poise. But the next time you read “no leakage found” in a report, remember they are not just words – they are your ship’s future protection.