A complete seafarer’s guide to Port State Control (PSC) inspections. Learn what PSC is, why it matters, what inspectors check, common deficiencies, rank-wise preparation tips, toolbox meetings, risk assessments, and how to avoid detention.

Introduction

The words “Port State Control boarding today” can make even the most experienced crew tighten up. Suddenly, every logbook is checked, drills are rehearsed, and everyone is on alert.

A PSC inspection is not just about the ship it is a test of the entire crew’s professionalism and preparedness. Fail to prepare, and the vessel risks deficiencies, detentions, fines, and reputational damage. Prepare well, and the inspection becomes smooth, quick, and even confidence-boosting.

This mega guide is written in simple, human style for cadets, junior officers, chief officers, and masters. It covers everything from what PSC is to how to prepare rank by rank, with risk assessments, toolbox meetings, and pro tips included.

By the end, you’ll have a complete roadmap to handle any PSC boarding with confidence.

- What is Port State Control (PSC)?

Port State Control (PSC) is the inspection of foreign-flagged ships in national ports to verify compliance with international conventions. It acts as a safety net to catch substandard ships that could endanger lives, the marine environment, or fair working conditions.

Who conducts PSC?

PSC is carried out by Port State Control Officers (PSCOs). They are authorised to:

Board vessels at port.

Check certificates, equipment, and crew competence.

Raise deficiencies.

Detain ships if safety is compromised.

- The Global PSC Network (MOUs)

The world is divided into regions with PSC regimes known as MOUs (Memorandums of Understanding):

Paris MOU – Europe & North Atlantic

Tokyo MOU – Asia-Pacific

Indian Ocean MOU – South Asia & Indian Ocean

Mediterranean MOU – Southern Europe & North Africa

Caribbean MOU – Caribbean

Black Sea MOU – Black Sea states

Riyadh MOU – Middle East

USCG – United States (independent regime, very strict)

Each MOU publishes annual reports with:

Detention rates

Common deficiencies

Flag state performance (white, grey, black lists)

Ships from black-listed flags are inspected more aggressively.

- Why PSC Inspections Matter

Protect lives: Lifeboats, firefighting systems, and navigation equipment are checked to prevent accidents.

Protect the environment: MARPOL compliance avoids oil, sewage, and garbage pollution.

Protect seafarers’ rights: PSC enforces MLC (working/rest hours, accommodation, contracts).

Protect careers: Officers are directly questioned. Inability to answer affects professional image.

Protect the company: Detentions mean delays, loss of charters, and heavy costs.

- When and Where Do PSC Inspections Happen?

PSC inspections happen whenever a foreign ship enters port, but not all ships are checked equally.

Targeting factors

Ship’s age – Older than 15 years = high risk.

Flag performance – Black/grey list flags = higher chance.

Company performance – Poor ISM history = more inspections.

Ship type – Bulk carriers, tankers, passenger ships are targeted.

History – Repeat deficiencies lead to follow-up checks.

- What Do PSC Inspectors Check?

PSC covers six key areas:

5.1 Certificates & Documentation

Safety Equipment, Safety Construction, Safety Radio, Load Line, IOPP, ISM, ISPS, DOC, SMC, MLC.

Logbooks: Oil Record Book, Garbage Record Book, Ballast Water Record Book, GMDSS log, Official Log.

Crew documents: COCs, endorsements, medicals, training records.

5.2 Life-Saving Appliances (LSA)

Lifeboats: condition, release gear, engines.

Fall Preventer Devices (FPDs) fitted during drills.

Liferafts and hydrostatic releases.

Rescue boat readiness.

5.3 Firefighting Appliances (FFA)

Fire extinguishers and hoses.

Fire pumps and hydrants.

BA sets and EEBDs.

CO₂ fixed system with records of testing.

5.4 Navigation

Passage plan berth-to-berth.

ECDIS updated with latest permits.

Radar, gyro, echo sounder, GPS, compass.

NP133C and Notice to Mariners.

5.5 Pollution Prevention

OWS and 15 ppm monitor.

Oil Record Book accuracy.

Garbage management.

Ballast Water Treatment compliance.

5.6 ISM & Crew Competence

Drills: fire, abandon ship, enclosed space.

Crew knowledge of duties.

SMS familiarity.

5.7 Maritime Labour Convention (MLC)

Food, catering, hygiene.

Rest hours compliance.

Valid employment contracts.

- Common Deficiencies Found in PSC

Lifeboat release gear defects.

FPDs not fitted during drills.

Fire pumps not working.

OWS tampering or bypass.

Incomplete Oil Record Book entries.

ECDIS not updated.

Hours of rest manipulated.

Expired medical certificates.

Dirty galley or poor food standards.

Ships detained for lifeboat accidents, falsified logbooks, and OWS bypass are common in reports.

- Rank-Wise Preparation for PSC

Cadets

Learn location of all LSA/FFA.

Be ready to demonstrate equipment (EEBD, SCBA donning).

Know your muster station.

Third Officer

Ensure LSA and FFA maintenance records are updated.

Keep navigational charts and ECDIS fully corrected.

Prepare GMDSS log and drill records.

Chief Officer

Responsible for cargo, ballast, LSA/FFA condition.

Ensure lifeboats, rafts, and fire plans are up to date.

Lead drills with risk assessments and toolbox meetings.

Chief Engineer

Prepare OWS, incinerator, sewage system.

Verify engine room logbooks and pollution prevention equipment.

Master

Ensure all statutory certificates are valid.

Conduct pre-arrival safety meetings.

Be ready for direct questioning from PSCO.

Maintain professional cooperation without over-volunteering information.

- Risk Assessment and Toolbox Meetings for Drills

Every PSC-observed drill should begin with:

Risk Assessment: Identify hazards (e.g., lifeboat falling, slips, manual handling). Assess likelihood, consequences, and controls.

Toolbox Meeting: Brief crew on step-by-step procedure, roles, PPE required, and emergency stops.

Example: Lifeboat Lowering Drill

Hazards: Fall of boat, hook failure, crush injuries.

Controls: FPDs fitted, lower empty boat first, use embarkation ladder for crew, emergency stop tested.

Toolbox: Allocate roles (winch operator, painter man, engine starter), confirm radios, stand-by crew at hooks.

This structured approach impresses PSC inspectors and keeps drills safe.

- PSC and Lifeboat Drills

PSC pays special attention to lifeboat drills because they have caused many seafarer deaths.

Use FPDs when lowering.

Lower empty boat where possible, crew to embark via ladder.

Test engine in water, not on deck.

Record drill in logbook with details.

File risk assessment and toolbox talk in SMS records.

- How to Handle a PSC Inspection Onboard

- Initial Boarding

Welcome inspector politely.

Inform Master and duty officer.

Escort them as per ISPS procedures.

- During Inspection

Answer clearly, don’t guess.

Show documents confidently.

Demonstrate equipment as asked.

- After Inspection

Review deficiency report.

Correct minor items immediately.

Record corrective actions in SMS.

- Pro Tips to Avoid PSC Detention

Keep a PSC file ready with all major certificates and last 3 months’ drill records.

Do a pre-arrival internal audit 24 hours before port.

Logbooks should be neat, updated, and error-free.

Store oil samples properly, PSC may ask.

Keep accommodation and galley clean.

Train crew to answer common PSC questions (e.g., “Show me EEBD donning”).

- Conclusion

A PSC inspection should not be seen as a threat, but as an opportunity to prove professionalism and ensure safety. Ships that prepare daily, drill correctly, and maintain records honestly never fear PSC.

- Real Case Studies: Lessons from PSC Inspections

Case Study 1: Lifeboat Accident

Situation: Bulk carrier had a lifeboat drill, but hooks were not reset properly and no FPDs fitted.

PSC Finding: Release gear unsafe, crew at risk.

Lesson: Always fit FPDs and prefer ladder embarkation to reduce crew in boat during lowering.

Case Study 2: Missing Certificates

Situation: Passenger ship certificates expired by 1 month; crew unaware.

PSC Finding: Multiple deficiencies; detention threatened.

Lesson: Master and D/O must monitor certificate expiry well in advance.

- Frequently Asked Questions (FAQs)

Q1: Can PSC inspect without notice?

Yes. Most PSC inspections are unannounced. Targeted ships may be boarded immediately upon arrival.

Q2: What happens if the ship refuses inspection?

Refusal can lead to detention, fines, or denial of port entry. Never refuse; cooperate professionally.

Q3: How often must lifeboat drills be conducted?

Minimum once every 3 months, as per SOLAS Chapter III, Regulation 19.

Q4: What documents should be ready?

Certificates, logbooks, crew COCs, STCW records, ISM manuals, pollution control records, ballast and oil records, and PSC file.

Q5: Can cadets demonstrate lifeboat drills?

Yes, under supervision. PSC may ask cadets to explain or operate basic equipment.

Q6: What are the top PSC deficiencies to watch for?

LSA and FFA not functional

Lifeboat hooks or FPDs unsafe

OWS tampering

Navigation charts not updated

Logbooks incomplete

- Step-by-Step PSC Preparation Plan (Master Checklist)

- Certificates & Documentation

Check all statutory certificates

Ensure crew COCs are valid

Logbooks up to date

- Drills & Crew Competence

Conduct lifeboat and fire drills

Check EEBDs, SCBA, lifeboats, and FPDs

Verify hours of rest compliance

- Pollution Prevention

Test OWS and separators

Check Garbage Record Book

Verify ballast water treatment records

- Navigation & Passage Planning

Update charts and publications

Verify ECDIS corrections

Check bridge equipment functionality

- Toolbox & Risk Assessment

Hold pre-inspection meeting

Assign roles and responsibilities

Review high-risk areas and controls

- Physical Inspection Readiness

Ensure accommodation, galley, and mess areas clean

Ensure fire hoses, extinguishers, lifeboats ready

PPE available for inspection demo

- Final Checks

Master & D/O pre-brief crew

PSC file ready for quick review

Communication plan confirmed for boarding

- Pro Tips from Real Sea Experience

Mock PSC audits: Conduct internal audits before every foreign port.

Crew awareness: Rotate responsibilities so everyone is familiar with PSC procedures.

Lifeboat handling: Fit FPDs before lowering; prefer ladder embarkation to avoid injuries.

Logbooks & records: Always be honest; show corrective actions if issues exist.

Communication: Speak clearly, politely, and professionally to PSCOs.

Keep up with MOU bulletins: Paris/Tokyo MOU release annual reports with trends and targeted deficiencies.

- Digital Tools to Support PSC Preparation

E-logbooks & digital certificates: Easier to update and present to inspectors.

Checklist apps: Track last inspections, drill dates, and crew competence.

SMS integration: Store risk assessments, toolbox talks, and PSC files digitally for instant access.

- Psychological Preparation for Crew

PSC inspections can be stressful. Training officers and cadets to:

Remain calm

Answer honestly without guessing

Demonstrate familiarity with equipment

Respect the inspector’s authority

This mindset ensures confident, smooth inspections, reducing errors and deficiencies.

- Beyond the Inspection: Continuous Improvement

PSC isn’t a one-time exercise; it’s a feedback loop. After every inspection:

- Review deficiencies and lessons learned.

- Update SMS manuals and checklists.

- Conduct internal drills and audits to prevent recurrence.

- Train new crew and cadets based on PSC findings.

Ships that embrace continuous improvement often never see repeated detentions.

- Conclusion: Mastering PSC Inspections

PSC inspections are more than audits; they are opportunities to verify ship safety, crew competence, and environmental compliance.

With proper preparation:

Conduct toolbox meetings and risk assessments

Ensure all certificates and logbooks are up to date

Perform realistic drills with FPDs

Keep accommodation and equipment clean

Train crew in communication and professional demeanor

A well-prepared ship is respected by inspectors, safe for the crew, and compliant with international regulations.

Remember: PSC readiness is not for the inspector — it’s for your safety, your career, and the ship you command.

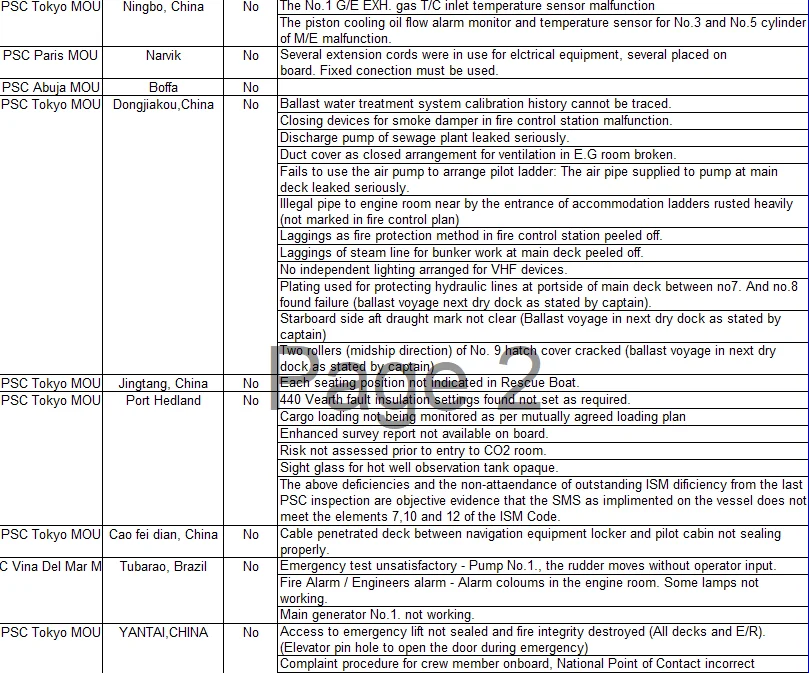

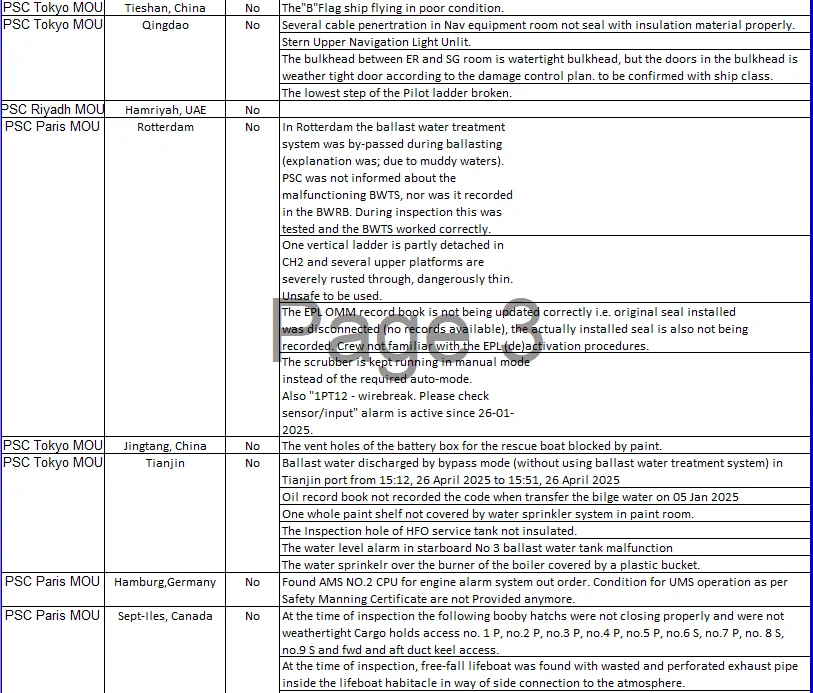

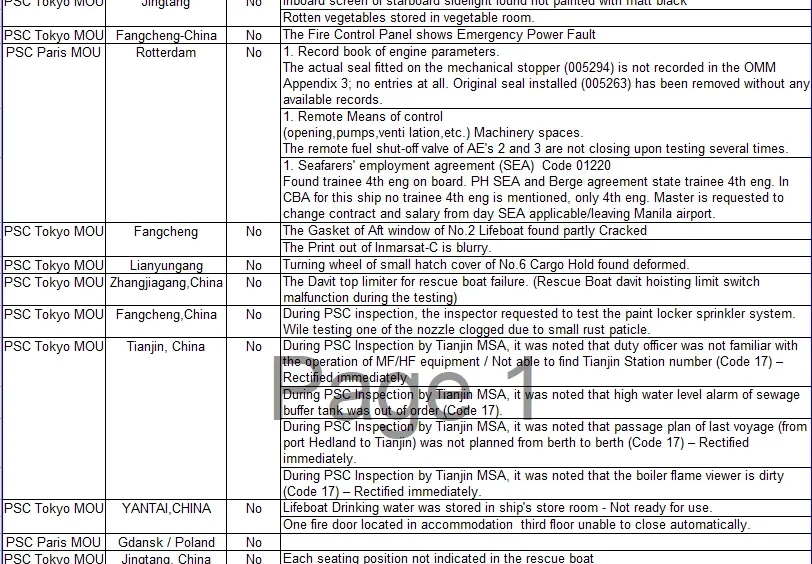

Below is a list of sample deficiencies for reference