As you prepare for your journey as a Fourth Engineer onboard, one of the first pieces of machinery you will interact with on a daily basis is the air compressor. This might look like another piece of heavy equipment in the engine room, but its role is far more important than what meets the eye. Understanding its construction, working principle, and practical applications is essential for your professional growth.

What Is an Air Compressor?

Simply put, an air compressor is a mechanical device that compresses air, reducing its volume and increasing its pressure. This compressed air is one of the lifelines of a ship’s operation, powering everything from starting engines to operating control valves and service auxiliaries.

Think of compressed air as the “silent helper” of almost every shipboard system. Without it, we cannot even start the main engine.

Types of Air Compressors You Will Encounter Onboard

By Function:

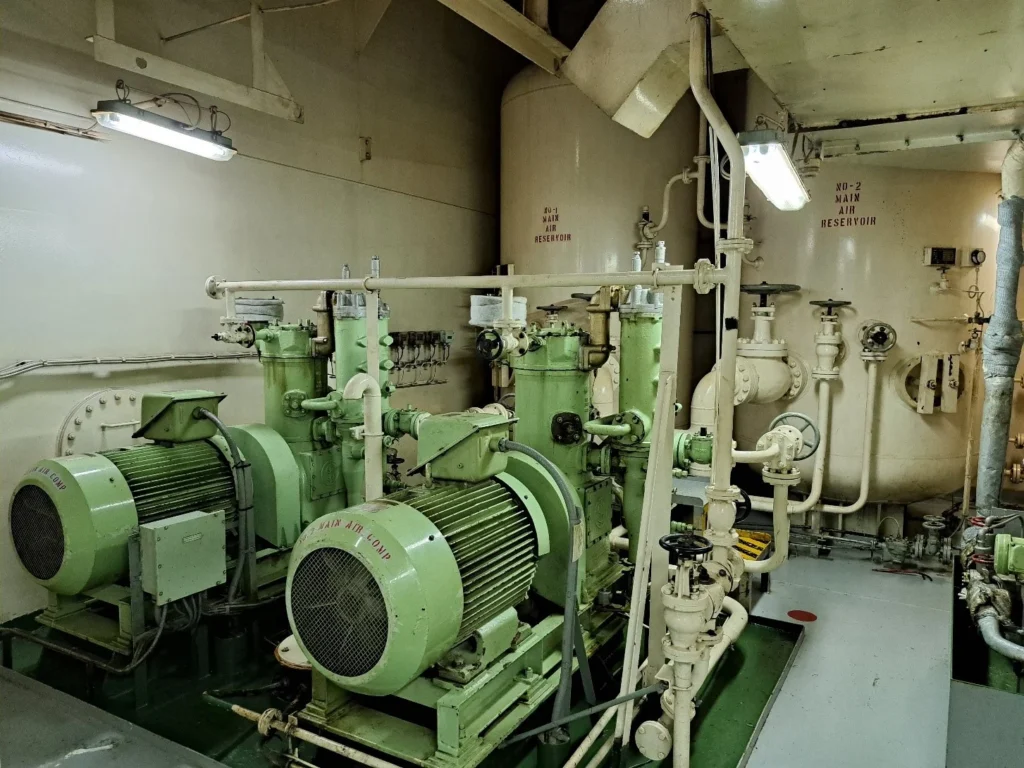

- Main Air Compressor – Supplies highly pressurized air (up to 30 bars) to start the main and auxiliary engines.

- Topping-up Compressor – Maintains air pressure when leakage causes pressure drops in the system.

- Deck/Service Air Compressor – Supplies low-pressure air (6–8 bars) for deck operations, service air, and control systems.

Emergency Air Compressor – Provides compressed air to start auxiliary engines during emergencies if the main system fails.

By Design:

- Centrifugal Compressor

- Rotary Vane Compressor

- Rotary Screw Compressor

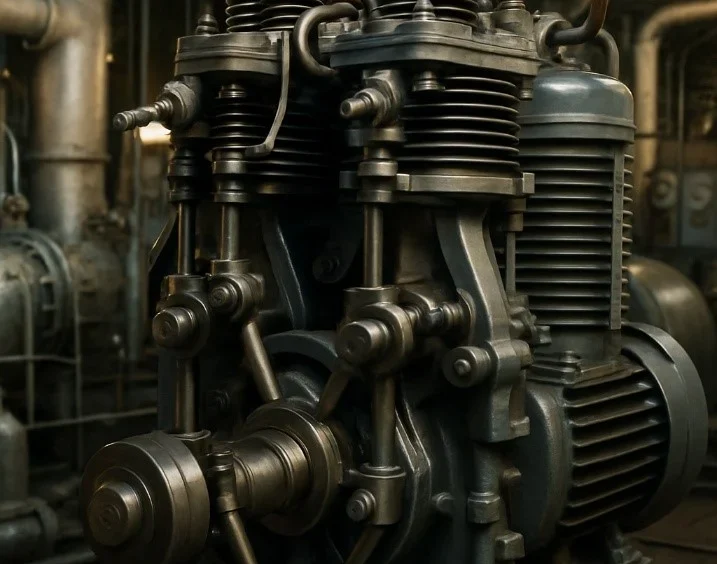

- Reciprocating Compressor (widely used onboard)

For marine practice, the reciprocating air compressor is the most common type.

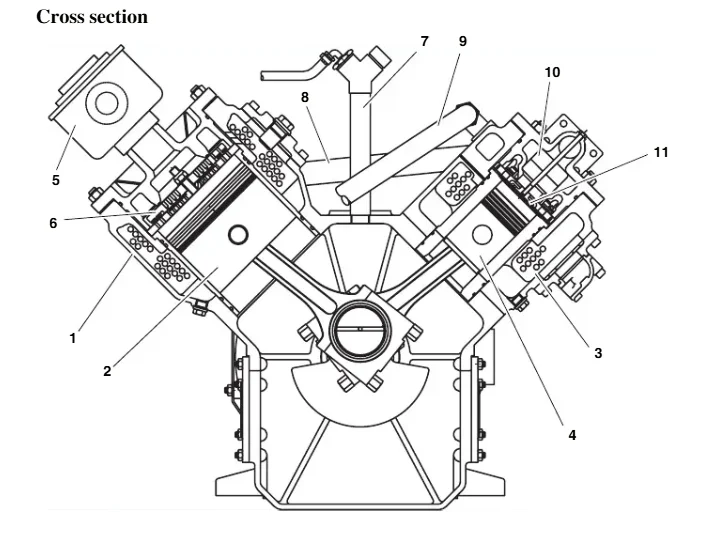

How Does a Reciprocating Air Compressor Work?

Visualize it like the engine of a car running in reverse. Instead of fuel intake and exhaust, we have:

- Suction stroke: The piston moves down, reducing pressure in the cylinder. This opens the suction valve and air is drawn in.

- Compression stroke: The piston moves up, compressing the air and increasing its pressure.

- Discharge stroke: When pressure reaches the desired level, the discharge valve opens, and compressed air is delivered to the air bottle.

This compressed air is later used for starting main engines or auxiliaries.

Applications of Compressed Air Onboard

For a junior engineer, linking theory to practice is important. Here are some common applications you’ll face during watchkeeping:

- Starting engines – Main and auxiliary engines rely on compressed air for their initial kick.

- Pneumatic tools – Used for cleaning, maintenance, and minor repairs.

- Control systems – Safety and maneuvering systems use compressed air for quick responsiveness.

- Whistles and foghorns – Essential for navigation and communication at sea.

- Hydraulic or lifting equipment – Often backed by compressed air systems.

- Boilers and refrigeration plants – Require compressed air during start-up.

Essential Components You Should Know

Every Fourth Engineer is expected to understand the main parts of the compressor system. These include:

- Power Source (Electric Motor/Engine drive) – Drives the compressor.

- Cooling System – Maintains temperature during multi-stage compression.

- Lubrication System – Reduces friction and wear, extending equipment life.

- Suction & Discharge Valves – Control air intake and delivery.

- Air Bottle – Stores compressed air under pressure.

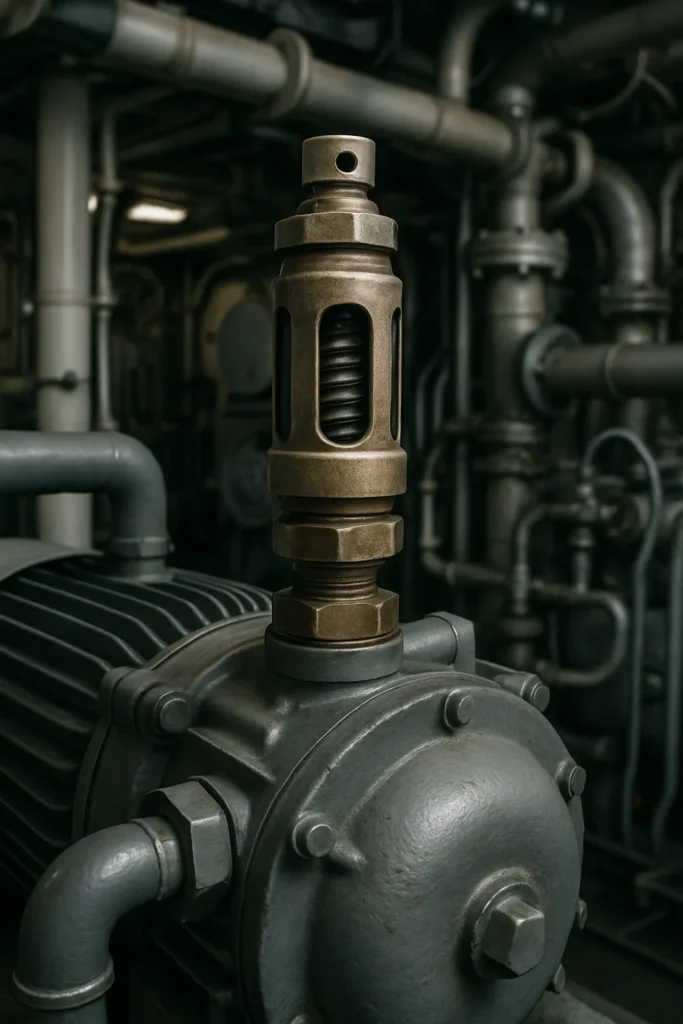

- Safety Devices – Pressure relief valves and alarms protect against overpressure.

Efficiency and Safety

As a professional, you will be expected not only to operate compressors but also to maintain their efficiency:

- Regularly check pressure gauges and never run the compressor below required pressure levels.

- Monitor safety valves and ensure they are functional at all times.

- Maintain lubrication and cooling water supply during operation.

- Always follow the SMS (Safety Management System) procedures of your vessel.

Remember: air compressors operate under high pressure, and negligence can result in serious accidents. Your personal safety and that of the ship depend on it.

Advice to Aspiring Fourth Engineers

When you step onboard, compressors will often be among the first machines assigned to you for maintenance. Take that responsibility seriously. Learn the normal running parameters, understand the sound and vibration of the machine when it is healthy, and always be observant. The knowledge you gain from maintaining compressors will form a foundation for handling more complex systems later in your career.

Air compressors may seem like small auxiliaries compared to main engines, but their importance cannot be overstated. As you prepare to join your vessel, make sure you invest time in understanding every aspect of their operation. A good engineer is one who can run the ship safely even when the big machines depend on the smaller ones.