For Reliquefaction Process — Insights from a Chief Engineer

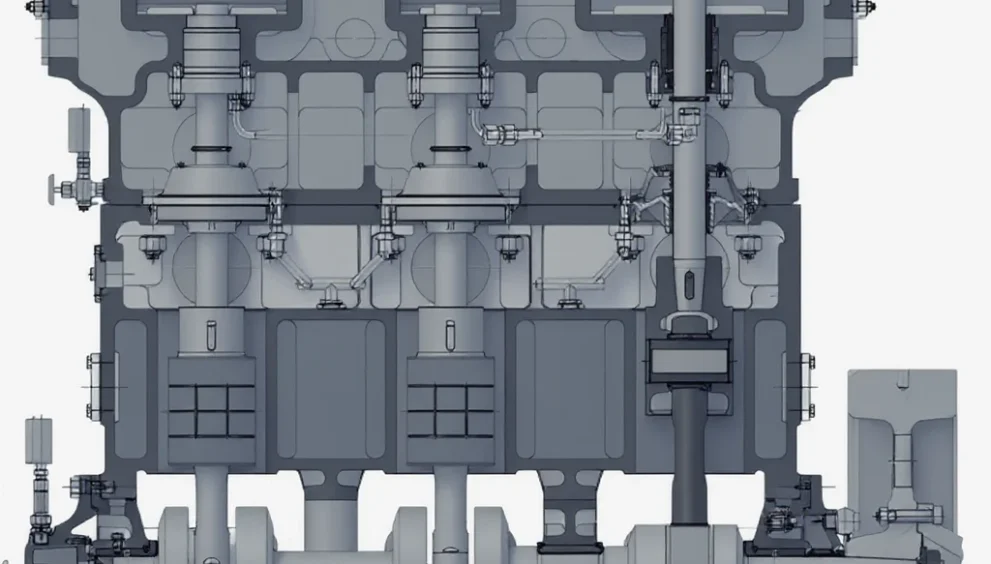

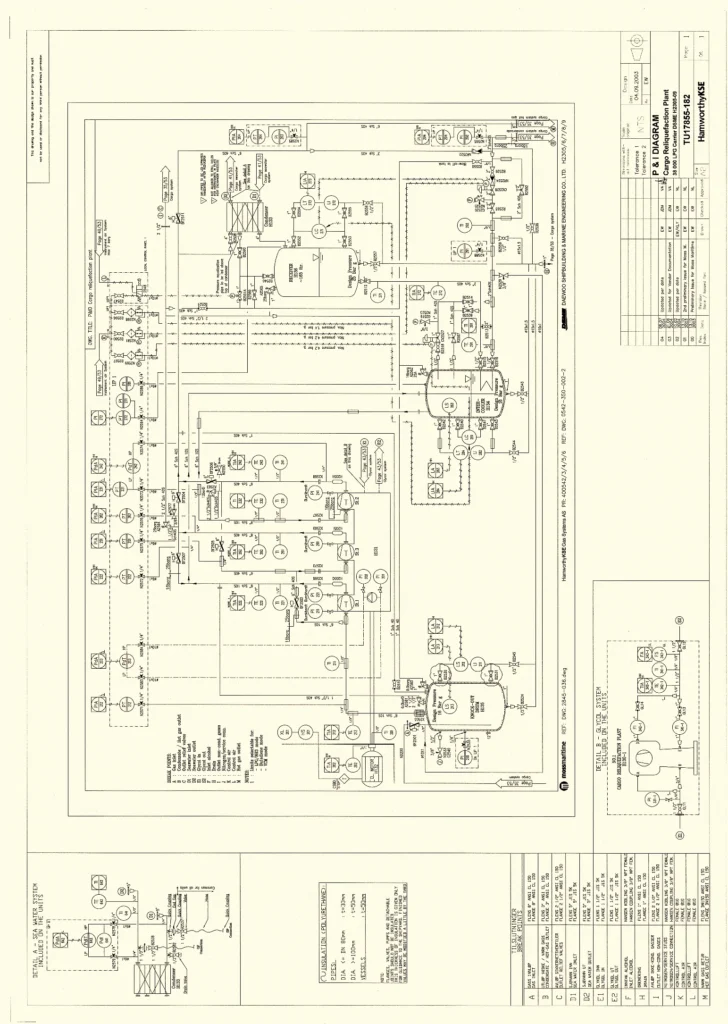

LPG cargo compressors are pivotal in the reliquefaction systems of LPG carriers. These compressors handle boil-off vapors (BOG) from the cargo tanks, compressing and conditioning the vapors to liquefy the gas and return it to the tanks, thereby maintaining pressure and minimizing cargo loss. Operating these compressors requires strict procedures, vigilance, and safety awareness.

Introduction to LPG Cargo Compressor in Reliquefaction(Cargo – Propane)

During the voyage, heat ingress causes vaporization of cargo inside the tanks, producing boil-off vapors. To prevent loss and maintain tank pressure, reliquefaction systems compress this vapor, cooling and condensing it back to liquid. The compressor is central to this; it must safely compress gaseous LPG under varying pressure and temperature conditions for effective condensation.

Starting the Reliquefaction Compressor

Critical Pre-Start Procedures

- Safety Devices: Ensure all mechanical and electrical safety devices are verified and functional.

- Oil Level Check: Confirm adequate lube oil in the crankcase via sight glass (about 1/2 full).

- Mechanical Condition: After maintenance or long inactivity, rotate flywheel manually in operational direction to check mechanical integrity. Remove barring devices before commissioning.

- Purge with Nitrogen: Purge compressor and piping thoroughly with dry nitrogen to remove air and moisture before handling LPG vapors (if starting after DD or Inerting)

- Valve Handling: Open suction stop valve cautiously; initially throttle if needed to prevent vapor condensation. Discharge stop valve must be fully opened before motor start.

- Coolant Flow: Verify proper circulation of cooling water or other coolants to avoid overheating.

- Motor Start: Energize motor while monitoring lube oil pressure rise (target differential ~4.0 bar). Confirm smooth motor acceleration without abnormal noise or vibration.

Continuous Operation and Monitoring

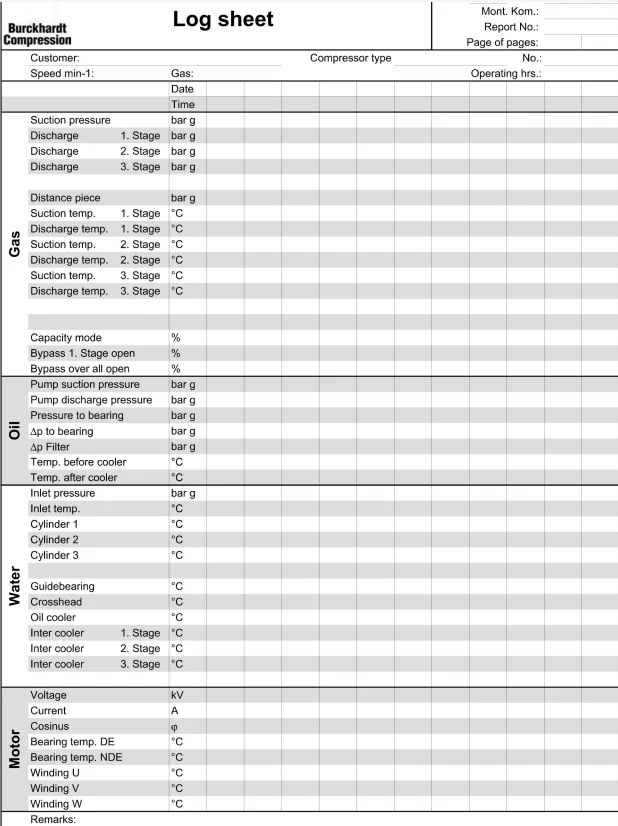

- Operate under constant supervision by trained personnel using detailed log sheets recording suction/discharge pressures, temperatures (including temperature after intercoolers and coolers), lube oil pressure, coolant temperature, and motor current.

- Maintain suction temperature above the dew point of LPG vapor to prevent liquid knock and ensure compressor safety.

- Control compressor capacity according to boil-off rate; some compressors provide staged capacity control (e.g., 50% and 100% load).

- Monitor cooling water temperature (typically 35°C–45°C) and avoid sudden temperature fluctuations.

- Limit shaft seal oil leakage to a maximum of three drops per minute.

Compressor Log Sheet

Stopping the Compressor

- Stop compressor maintaining full back pressure to mitigate abrupt pressure drops.

- Close suction and discharge valves based on system requirements.

- Continue coolant flow during compressor downtime to prevent condensation and oil contamination.

- In all cases where the gas pressure in the crankcase may exceed 8 bar when the compressor is stopped or where the gas may con dense, the trapped gas volume should be relieved slowly.

- For extended stoppage (>24 hours), isolate and preserve the compressor and consult technical service for specific measures including lubricant additive monitoring.

Safety and Gas-Specific Instructions

- Due to LPG’s flammability and toxicity, purging with inert dry nitrogen before and after maintenance is mandatory to prevent explosive atmospheres.

- Do not operate compressor with air in the system; gas evacuation protocols must be strictly followed.

- Safety valves are calibrated to precise pressure set points to protect compressor and piping integrity.

- Use only genuine parts for repairs; avoid unauthorized modifications or non-compatible lubricants.

- Regularly inspect valve conditions, piston wear, gasket seals, and flange connections to prevent leaks and malfunctions.

Troubleshooting Common Issues

- Sudden rise in temperatures or pressure differences between stages may indicate valve damage or piston wear.

- Cooling inefficiencies often result from sediment in cooling water channels or reduced coolant flow.

- Oil system problems like pressure loss or contamination require immediate rectification.

- Electric motor alarms for overcurrent or overheating can indicate mechanical binding or electrical faults.

Refer to manufacturer troubleshooting guides for detailed diagnostics and corrective actions.

Conclusion

The LPG cargo compressor is the heart of the reliquefaction system on LPG ships, and its correct operation is key to cargo preservation, safety, and effective voyage execution. By adhering to structured start-up, operational monitoring, and shutdown protocols, combined with rigorous safety procedures, marine engineers ensure the compressor’s reliable and safe performance.