What They Are and Why They Matter

If you’ve ever worked around a marine boiler, you know it’s not just some metal drum sitting in the engine room. It’s a workhorse giving us steam for everything from heating fuel to cargo operations, cleaning tanks, and more.

But to do all that safely and efficiently, boilers need a few helpers. That’s where mountings and accessories come in.

You’ve probably heard those terms during training or around the ship, but what do they really mean? And why are they so important?

Let’s break it down in a way that actually makes sense no textbook talk, just real-world stuff.

So, What Are Boiler Mountings?

Mountings are the must-have parts of a boiler the stuff that keeps it safe and under control. These aren’t optional. Every boiler, by law and design, needs them.

You can think of them like the safety gear on a car brake, seatbelts, airbags. They don’t help it go faster, but they make sure nothing goes terribly wrong.

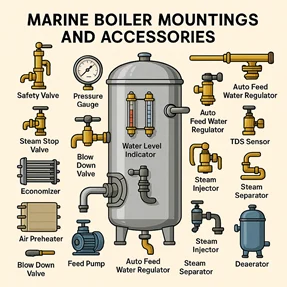

Common Mountings You’ll See Onboard:

- Safety valve – Releases pressure if it gets too high. This is your boiler’s emergency escape valve.

- Steam stop valve – Controls where steam goes. Basically, it decides when the boiler sends out steam and when it doesn’t.

- Vent valve – Gets rid of trapped air during start-up and lets air in when shutting down.

- Pressure gauge – Tells you how much pressure is inside the boiler. Always keep an eye on this.

- Water level indicator – Shows how much water is inside. Low water? Big trouble.

- Feed check valve – Stops water from flowing backwards into the feed line.

- Fusible plug – A smart little plug that melts if water gets too low and things overheat — it kills the fire before the boiler kills itself.

- Blow down valve – Helps remove sludge and dirt from the bottom.

- Scum blow down valve – Clears out surface impurities like foam and oil.

- Salinometer valve – Lets you take water samples to check the boiler water condition.

- Whistle valve – Yep, this one power the ship’s whistle.

- Low-level alarm – Sounds off if water levels get dangerously low.

- Soot blower – Blows soot off the tubes to keep them clean and efficient.

- Auto feed water regulator – Keeps the water level steady without manual input.

- Manhole – Allows someone (usually unlucky) to get inside for inspection or cleaning.

- Mud box – Collects the junk and sludge that comes out during cleaning.

- TDS sensor and sample line – Monitors water quality by checking for dissolved solids.

Why Do Mountings Matter?

Simple. They keep the boiler from becoming dangerous.

- They protect life and equipment — preventing explosions, dry firing, and pressure issues.

- They keep steam output steady — so you’re not guessing when you need power.

- They’re required by law — if they’re missing or not working, your ship fails inspection.

And What About Accessories?

Accessories are like your boiler’s personal trainers. They aren’t mandatory, but they help it perform better, use less fuel, and last a whole lot longer.

If mountings are about safety, accessories are all about efficiency.

Common Accessories That Make a Big Difference:

- Economizer – Uses exhaust gas to preheat feedwater. Saves fuel and gives the boiler a head start.

- Air preheater – Warms up the air before it goes into the furnace. Better combustion, better efficiency.

- Superheater – Increases the steam temperature. If you’ve got turbines, this one’s key.

- Feed pump – Pushes water into the boiler under pressure. No pump, no steam.

- Steam injector – A backup system. It uses steam pressure itself to feed water into the boiler if pumps are down.

- Steam separator – Removes moisture from steam so what you get is dry and high quality.

- Deaerator – Removes dissolved oxygen and carbon dioxide, which can cause corrosion if left unchecked.

Why Bother with Accessories?

Because they make your life easier and your boiler’s life longer.

- You burn less fuel

- You get better steam

- You protect the boiler from rust and scale

- You reduce the number of breakdowns and dirty jobs

Final Thoughts

At the end of the day, every marine engineer needs to understand these two things:

- Mountings keep the boiler safe.

- Accessories help it work better

Both play their part. Mountings are your first line of defence, while accessories help you get the best performance with the least stress. So next time you’re in the engine room and you pass the boiler, take a second to appreciate those little pieces working behind the scenes quietly doing their jobs, keeping steam flowing, and making sure the ship runs smoothly.