Overview and Safety

Maintaining a ship’s LPG cargo compressor demands a systematic approach that prioritizes both technical precision and safety at every stage. Before starting work, always ensure the compressor is shut down, depressurized, purged with nitrogen, and physically isolated from the main system. Strict adherence to plant and local safety protocols is essential—never compromise on lock-out, tagging, and atmospheric testing procedures.

Maintenance Preparation and Tools

To maintain reliability and safety, confirm the compressor is fully secured and all safety interlocks are in place before commencing work. Keep the supplied set of tools—including wrenches, eye bolts, and torque wrenches—clean and ready for use. Use only lubricants and cleaning agents specified by the manufacturer, and check every chemical’s compatibility with process gas.

Cylinder, Piston, and Running-In

The LPG compressor typically operates with oil-free labyrinth pistons running in multi-stage cylinders. The pistons must be run-in carefully with dry nitrogen after replacement—a slow, controlled ramp-up over several hours allows for thermal expansion and optimal wear-in, preventing premature failure due to abrasion or seizure. Always check diametrical clearances between piston and cylinder during major overhauls to prevent abnormal wear and shifting pressures.

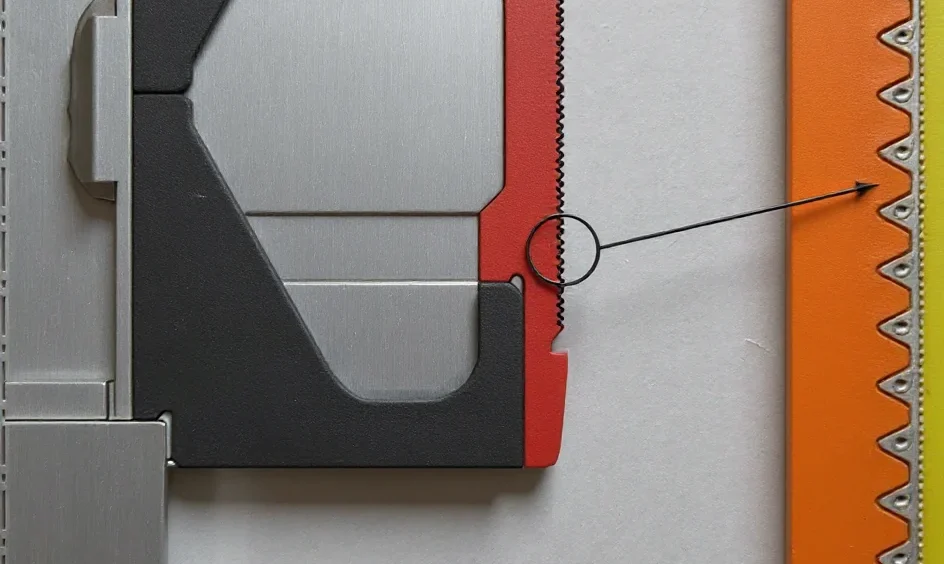

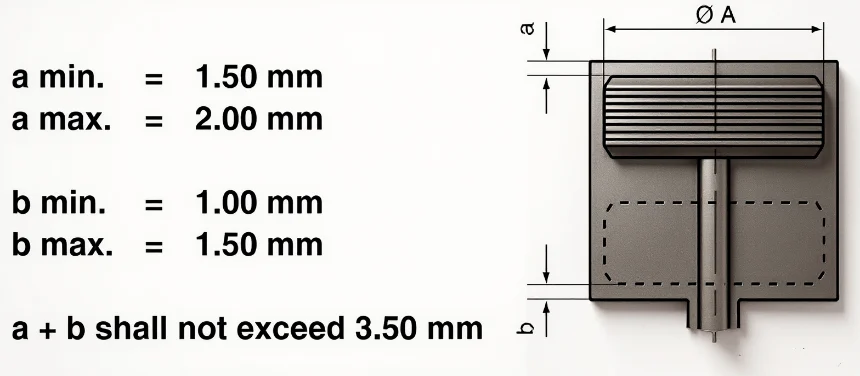

Checking of Piston Dead Clearance

The dead clearance can be measured with a lead wire or a feeler gauge which must be introduced through the valve openings (between piston and cylinder) at the T.D.C. and B.D.C. Wrongly measured or adjusted dead space clearances can cause

CAUTION

Wrongly measured or adjusted dead space clearances can cause major compressor failure.

Using too thick lead wire can lead to wrong measurement of dead space clearance b. Use lead wire of appropriate thickness or use a feeler gauge.

If there is no mix-up with the assembly, the dead space clearance must be adjusted with

distance washers of 0.5 mm thickness between the lower piston crown and piston rod

In case the piston must be removed, mark skirt, upper and lower crown. For the replacement of a piston rod, proceed according to makers instruction.

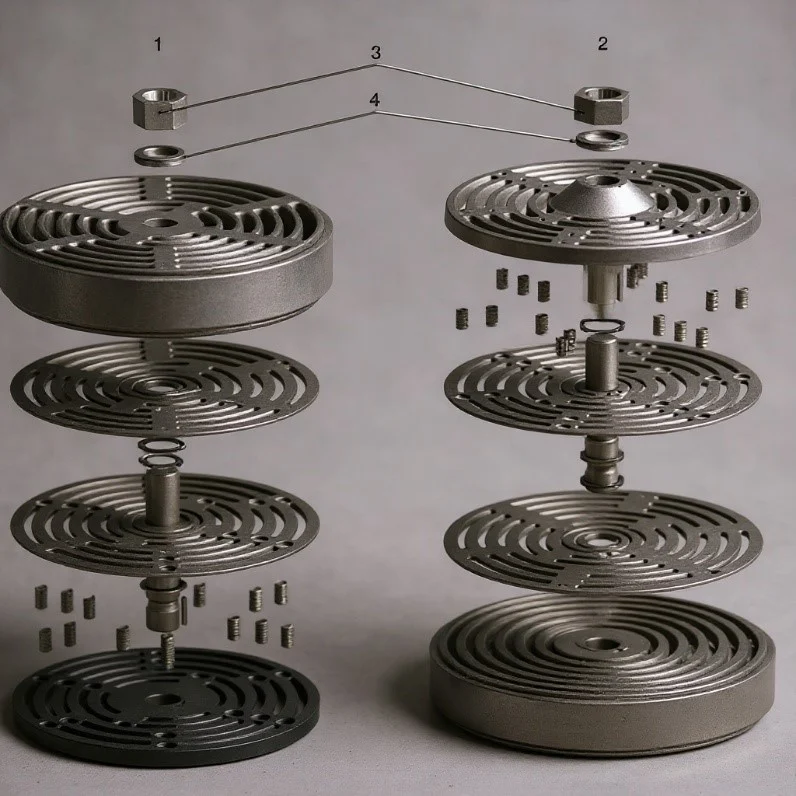

Valve Inspection and Assembly

Compressor valves are among the most sensitive components; inspect them every 6,000 to 8,000 hours, or more frequently if operational patterns shift. Cleanliness of all components in contact with process gas is paramount—ensure that every surface is oil and grease-free before assembly. Use the spring installation sequence strictly as advised, starting with the outermost circle and progressing inward.

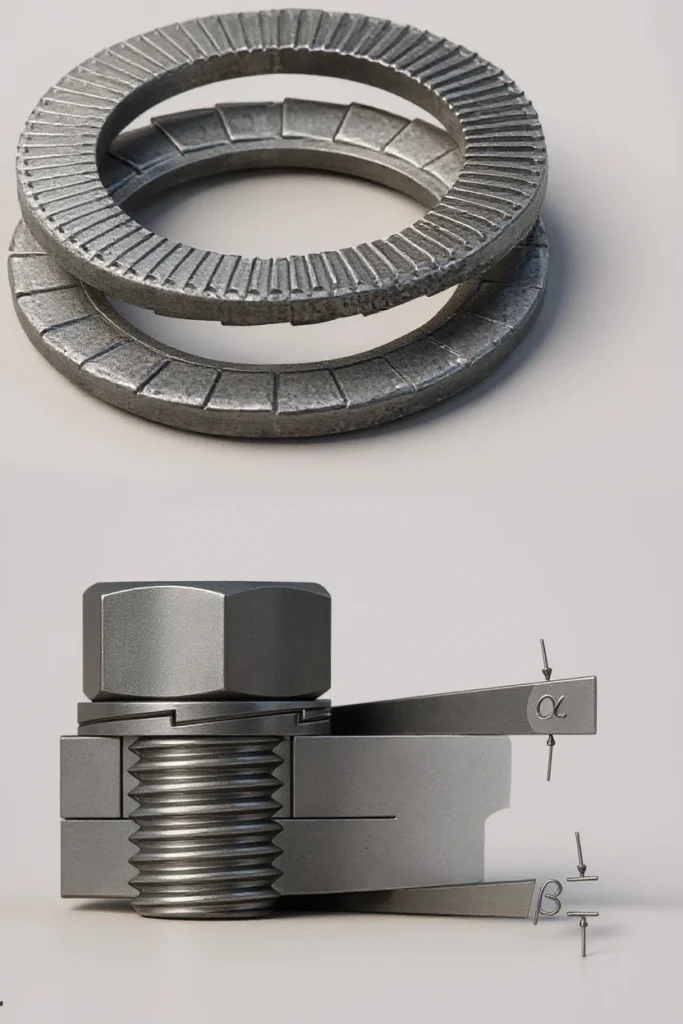

The centre bolt nut is secured by the “Nord-Lock® principle”. The “Nord-Lock®” washer has cams on one side with a greater angle than the pitch of the bolt. The washer has radial teeth on the side opposite and are installed in pairs, cam face to cam face.

The key is the difference in angles. When the bolt and/or nut is tightened, the teeth grip, seat the mating surfaces and lock preventing the washers from slipping. The interacting cams create a wedge action, thereby increasing the bolt tension and not allowing the fastener to rotate loose. The pair of washers expand more than the corresponding pitch of the thread. The unique bolt securing system uses tension instead of friction.

α > β = Locking effect

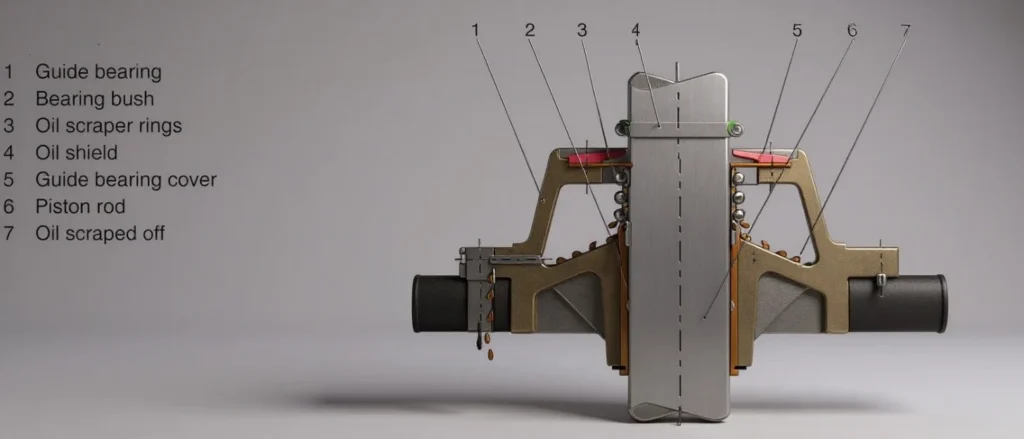

Piston Rod Packing and Oil Scraper Rings

Piston rod packings use graphite labyrinth rings. These seals must be inspected meticulously for wear, proper clearances, and absence of damage. Maintain the rod surface dry, smooth, and free from oil or defects above the oil shield area. When fitting oil scraper rings, stagger the inclined cuts 120° apart, and verify that positioning marks line up vertically.

Crankgear, Bearings, and Lubrication

The crankgear and bearings require careful attention to clearances and lubrication. Use only oils recommended by the manufacturer, suited for LPG applications and compatible with cargo gas chemistry. Periodically inspect the oil strainer, crankcase, and main bearings; measure all clearances with feeler gauges or dial indicators as per maintenance schedules. If the crankshaft deflection exceeds 0.08 mm, realign the motor before proceeding.

Troubleshooting and Common Faults

- Piston seizure, abnormal wear, or temperature spikes often indicate clearance issues or cooling failures.

- Valve malfunctions, such as failing to switch between load and no-load positions, frequently stem from faulty spring installation, excessive clearances, or incorrect control medium pressures.

- Frequent replacement of packing rings or persistent gas leaks may require revisiting assembly techniques, contacting OEM specialists, or adjusting ring quality and spring numbers.

Chief Engineer’s Guidance for Juniors

- Keep detailed log sheets of operational data, including temperature, pressure, and maintenance actions.

- Maintain strict discipline when marking and assembling components to avoid mismatches and optimize reliability.

- Never use non-genuine spares or substitute materials; such shortcuts risk safety and long-term operational integrity.

Final Notes

Successful LPG cargo compressor maintenance starts with safety and ends with quality control and diligent documentation. Approach each task methodically, consult OEM recommendations, and never hesitate to escalate complex issues to senior engineers or factory specialists.