Lifting devices like cranes and davits play a crucial role in a ship’s day-to-day operations. They are used to handle everything from provisions and spare parts to lifeboats and equipment in the engine room. Safety and reliability in action for the appliances should be assured through regular load testing — a method which tests compliance with regulations and operational integrity.

The answer lies in the Lifting Appliances Load Test

— A mandatory procedure carried out under class and statutory requirements. It ensures that cranes, davits, and lifting gear can safely handle loads beyond their Safe Working Load (SWL).

Recently, a vessel underwent such a test at YiuLian Dockyards (Zhoushan) Ltd, and the report offers a perfect example of how this process works.

What is a Lifting Appliances Load Test?

A load testing is a test where lifting equipment is checked for Safe Working Load (SWL) capacity at 1.25 or other agreed factor and registered at “TGTEST” on the report.

The safe working load (SWL) is the maximum weight that can safely be lifted by the crane on a regular basis.

Test load: The safe working load (SWL) the structure is capable, and passes, of withstanding during testing (often 1.25 x SWL) for structural test to breaking as well as for brake holding, limit switches and safety/emergency cut-outs.

As an example, a crane of 6-tonne SWL would be proof test-loaded at the rated load of 7.5 tonnes.

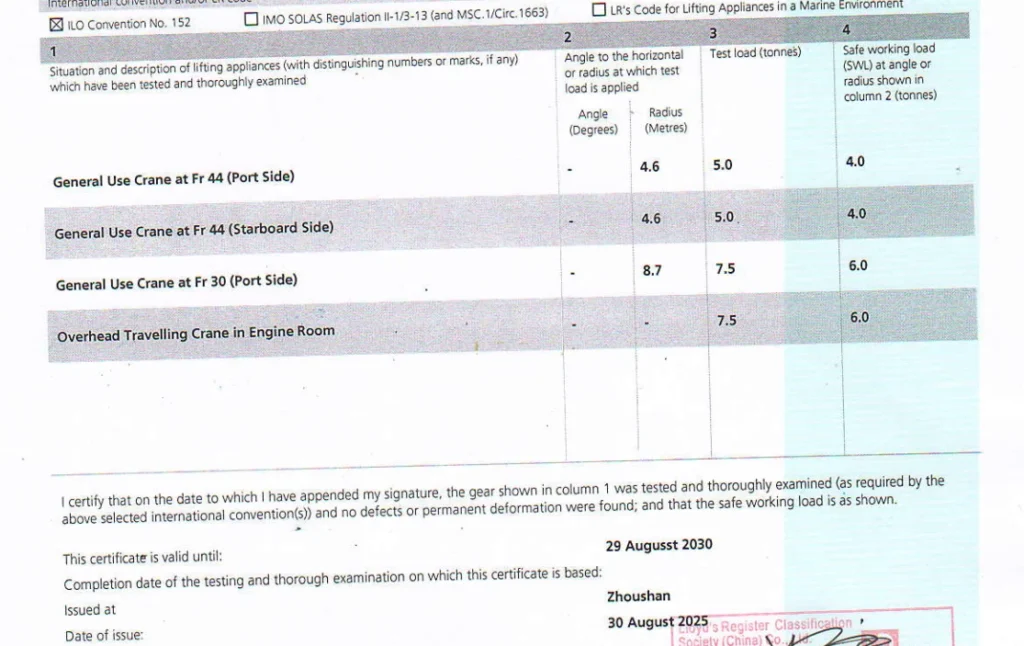

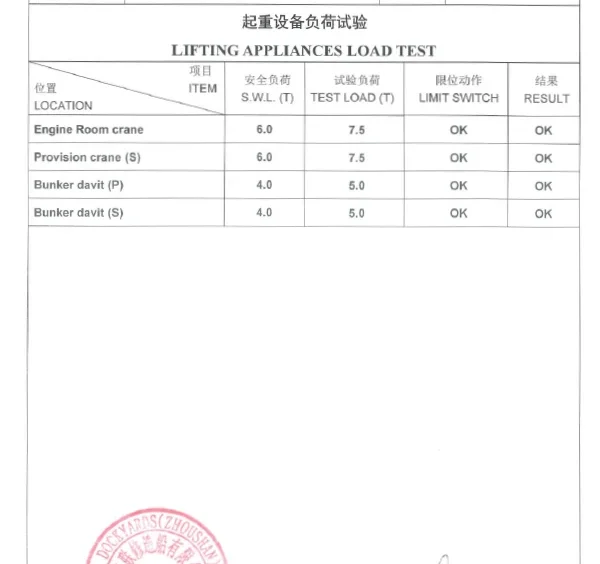

The inspection report dated 30th August 2025 shows the following lifting appliances were tested:

Engine Room Crane:

SWL: 6.0 T → Tested at 7.5 T → Result: OK

Provision Crane (S):

SWL: 6.0 T → Tested at 7.5 T → Result: OK

Bunker Davit (Port):

SWL: 4.0 T → Tested at 5.0 T → Result: OK

Bunker Davit (Starboard):

SWL: 4.0 T → Tested at 5.0 T → Result: OK

All appliances passed with limit switches functioning correctly.

Why is Load Testing Important?

1. Safety of Personnel

Failure of lifting gear can lead to severe injuries or fatalities. Testing ensures strength and reliability.

2. Regulatory Compliance

IMO conventions, ILO codes, and class rules require periodic testing of lifting appliances.

3. RightShip & PSC Inspections

Expired or missing load test certificates are common PSC deficiencies and 3rd party audit onbservations during inspections.

4. Operational Reliability

Load testing reveals weaknesses (cracks, faulty brakes, worn-out wires) before they cause accidents during cargo or engine operations.

How is a Load Test Performed?

1. Preparation

Visual inspection of structure, wires, sheaves, hooks, and brakes.

Verification of certification and identification plates.

Setting up calibrated test loads (weights or water bags).

2. Applying Test Load

Load applied at 1.25 × SWL as per class/IMO rules.

Equipment operated through full working range — lifting, lowering, slewing, and braking

3. Checking Limit Switches

Limit switches must stop movement before over-travel occurs.

Safety features such as overload protections are checked.

4. Post-Test Examination

Visual re-check for deformation, cracks, or damage.

Functional testing under normal SWL.

Test results recorded in official reports and endorsed by inspector/surveyor.

Regulatory References

ILO Convention No. 152 – Safety in the use of lifting appliances.

SOLAS Chapter II-1 – Structural strength and equipment safety.

IMO MSC/Circ. 1206/Rev. 1 – Maintenance and inspection of davits and cranes.

Society Rules (LR, DNV, ABS, BV, ClassNK): Specify test loads and certification criteria.

What Seafarers Must Know

Certifications: Each davit and crane should be supported with a current load testing certificate on board the vessel.

Pre-operation examination: Prior to operation, always check hooks, wires, sheaves and brakes no matter what the certification.

Log keeping: Record lifting gear checks in the deck logbook and PMS (Planned Maintenance System).

Reporting: Any abnormal sound, jerky movement, or slippage must be reported immediately.

Pro Tip from a Master

During inspections, surveyors often ask:

When was your last lifting appliance load test?

Always keep the latest certificates handy in the Ship Safety File or SMS Records. This shows good preparedness and prevents embarrassing situations during PSC or RightShip audits.

Conclusion

The Load Testing of Lifting Appliances is not just another box to tick. It is an essential safety measure that can save lives and maintain safe shipping operations as well as keep vessels compliant to international standards.

For the mariner, understanding the importance and keeping accurate documentation on the the Lifting Appliances Load Test is part of being responsible and competent.