Marine control air dryers play a crucial role in ensuring the quality and reliability of compressed air systems onboard ships. Compressed air taken in from the atmosphere contains water vapor and numerous contaminant particles which, when compressed, can precipitate as moisture and aggressive contaminants inside the piping system. This moisture combined with oil and heat causes corrosion, damages valves and control devices, and increases maintenance costs. An air dryer removes this moisture, ensuring dry compressed air, which is safer, more economical, and prevents machinery downtime.

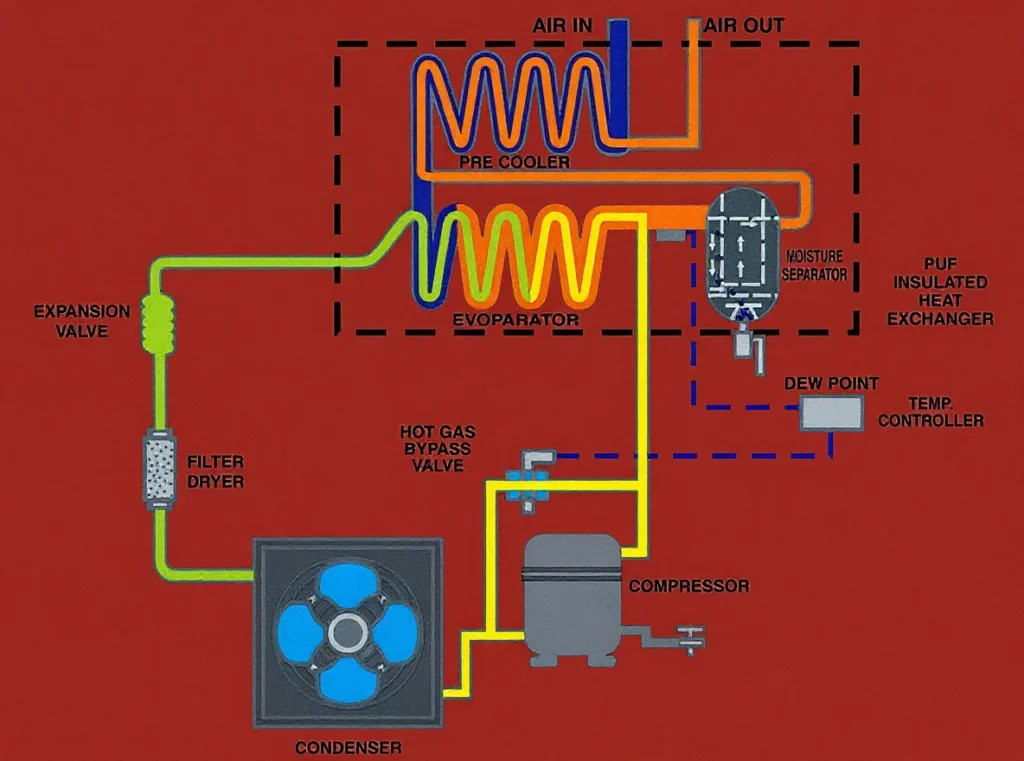

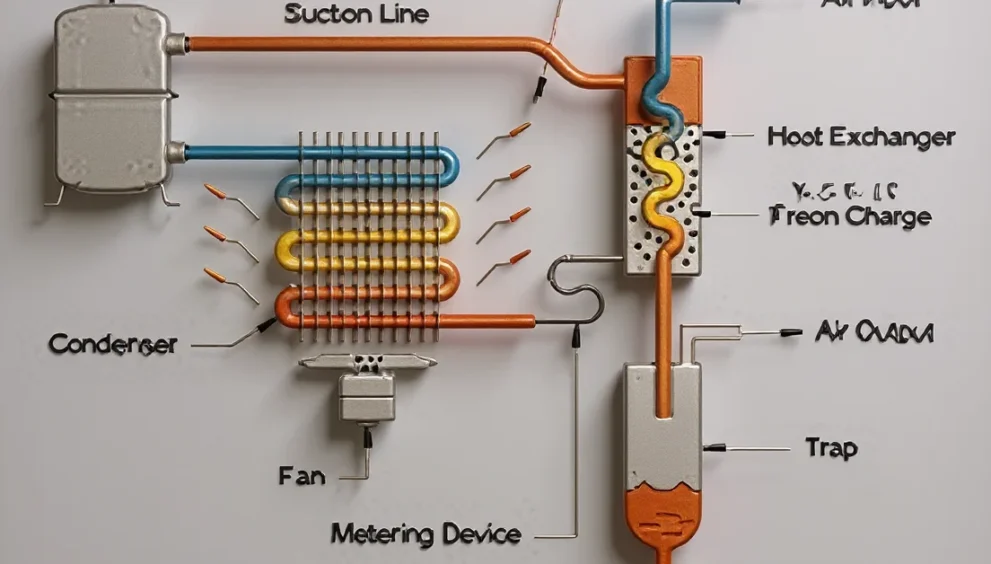

The most common marine air dryers use refrigeration to cool the compressed air, causing moisture to condense out and be drained away. These systems are factory tested and charged with refrigerant, designed to meet the highest standards of quality and durability.

Operation of Marine Control Air Dryer

Installation and Location

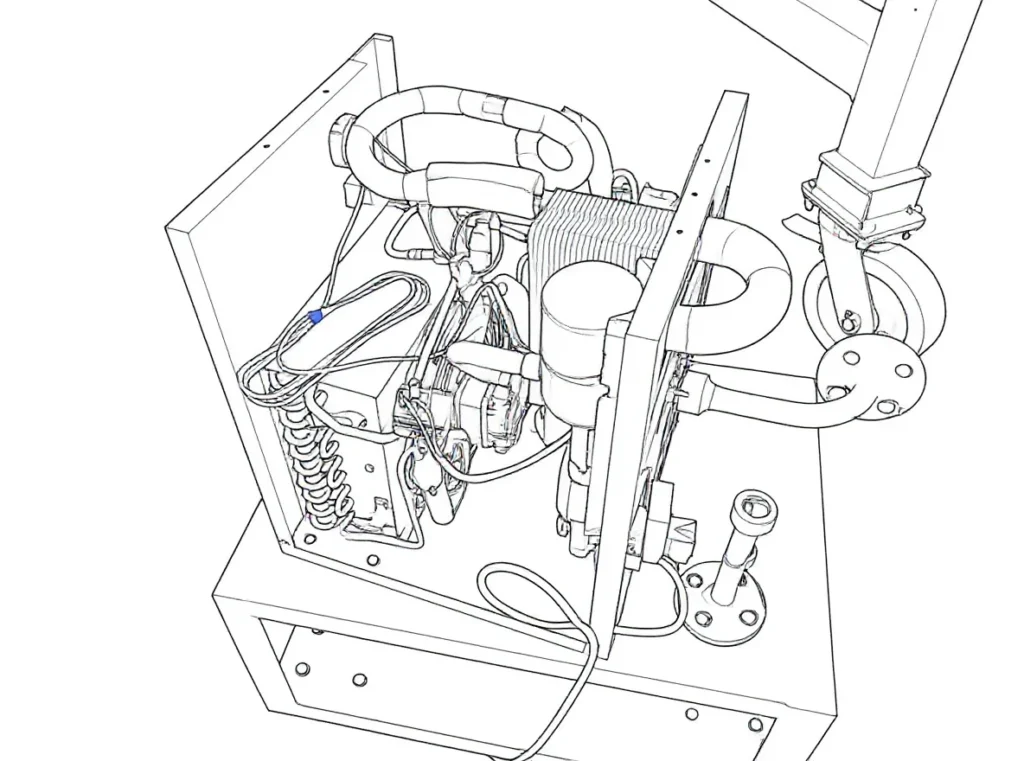

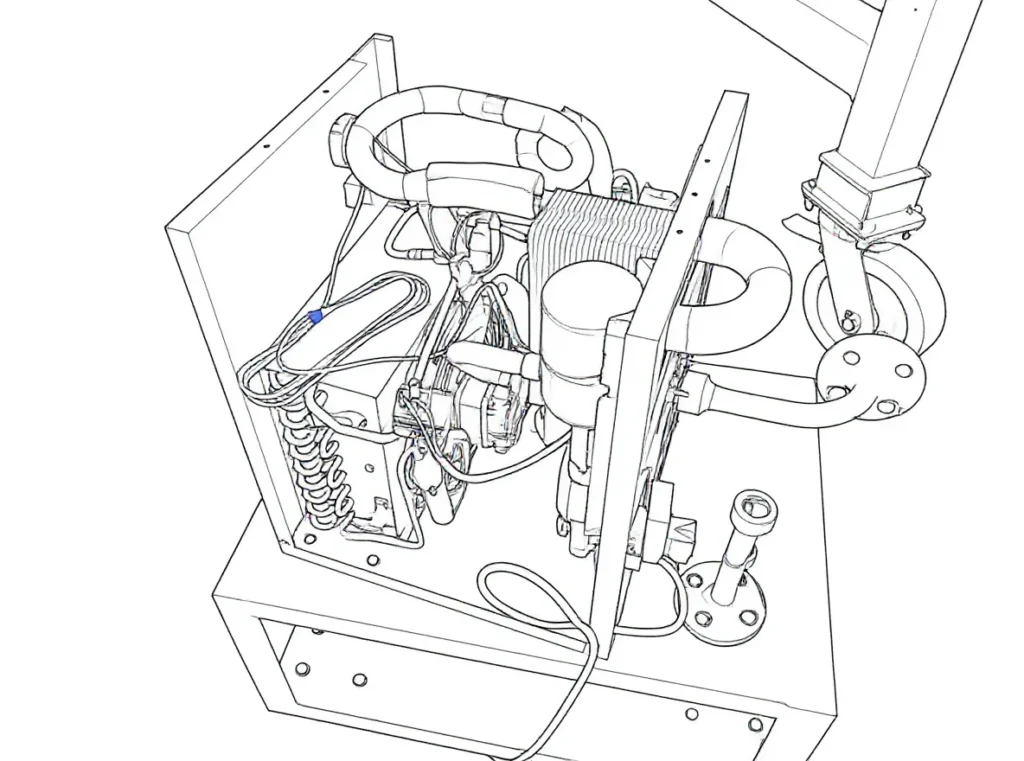

Marine refrigerated air dryers are typically installed downstream of the receiver tank. The compressed air line connects the receiver tank outlet to the dryer inlet, and the dry air outlet is piped into the distribution system. A bypass line should be installed to allow air system operation when the dryer is under maintenance.

Startup Procedure

- Before starting, all compressed air piping should be purged of debris like rust, weld slag, and moisture.

- Electrical installation must be verified by a qualified electrician, ensuring proper voltage, amperage, and fused disconnects.

- After connecting power and fluid lines, the dryer is started. Refrigerant suction pressure and temperature are monitored to be within normal range (for example, 45.9 BARG and 0-10°C for R-404 refrigerant).

- Allow the dryer to run for about 10 minutes before opening inlet and outlet valves and closing the bypass valve.

- The dryer should operate for at least one hour to stabilize, with possible adjustment of hot gas bypass valves or refrigerant pressure to achieve desired operating parameters.

Drain System

- The drain system automatically removes condensed water from the moisture separator.

- Drain ON and OFF intervals are adjustable to ensure efficient water removal without air loss.

- Proper drain timing prevents moisture carryover or excessive water accumulation.

Maintenance of Marine Control Air Dryer

Routine Service Checks

- Ensure bypass valves and air inlet/outlet valves are properly operated according to maintenance needs.

- Inspect and clean heat exchangers routinely; backflush if necessary with copper-compatible solvents.

- Test and clean or replace drains to maintain proper water expulsion.

- Address refrigerant compressor issues, such as overloads or cycling due to high/low pressure faults, by consulting troubleshooting guides.

- Monitor air flow and inlet air temperature to confirm system capacity matches demand; upgrade if necessary.

Troubleshooting Common Issues

- Compressor fails to start or hums without running could indicate electrical faults or mechanical problems.

- Cycling problems can arise from thermostat settings, pressure cut-outs, or refrigerant levels.

- Continuous running or frequent cycling may indicate refrigerant shortage, faulty temperature controls, or poor cooling.

- Capacitor and relay issues affect compressor motor starting and running performance.

- Frosting or sweating on suction lines indicates potential problems with evaporation or expansion valves.

Best Practices

- Use proper refrigerants as specified on the nameplate.

- Report and repair any transport or installation damage immediately.

- Follow manufacturer instructions for installation, operation, servicing, and safety precautions.

Conclusion

Marine control air dryers ensure that compressed air systems onboard ships deliver dry, contaminant-free air critical for system safety and longevity. Understanding their operation, installation requirements, and regular maintenance practices is essential knowledge for students aspiring to marine engineering roles. Effective care of these systems reduces corrosion, equipment downtime, and operational costs while maintaining ship safety and performance.

mohit jangid

08th Jan 2026testing