A step-by-step guide to emergency steering drills on ships. Learn SOLAS requirements, detailed procedures, risk assessments, crew duties, common PSC observations, and pro tips to pass inspections and stay prepared.

Introduction

A ship without steering is like a car without brakes. Steering failure at sea is one of the most dangerous emergencies a vessel can face especially in congested waters, near ports, or during pilotage.

That’s why emergency steering drills are mandatory under SOLAS and are closely scrutinised by Port State Control, Flag States, RightShip, and Class surveyors. These drills test whether the crew can shift from automatic steering to manual or emergency steering smoothly and without confusion.

In this blog, we will cover:

Why emergency steering drills are important

SOLAS and statutory requirements

Planning the drill (risk assessment and toolbox meeting)

Step-by-step procedure for conducting an emergency steering drill

Duties of Master, deck officers, engineers, cadets, and ratings

Common PSC/RightShip findings

Pro tips to make your drill realistic and inspection-ready

Why Are Emergency Steering Drills Important?

Preparedness: A steering gear failure in restricted waters can cause groundings or collisions.

Familiarisation: Ensures all bridge and steering gear room crew know their duties and locations.

Compliance: SOLAS makes these drills compulsory every three months.

Inspection readiness: PSC inspectors often demand to see a live emergency steering demonstration.

Confidence: Crew gain hands-on practice operating local steering controls, hydraulic pumps, and emergency communication.

SOLAS Requirements for Emergency Steering Drills

As per SOLAS Chapter V, Regulation 26:

Emergency steering drills must be conducted at least once every three months.

The drills must include:

Operation of the steering gear using the emergency power supply (if provided).

Operation of the rudder by local control (steering gear room).

Communication procedures between bridge and steering gear compartment.

Operation of alternative steering positions (if fitted).

The drills must be recorded in the logbook.

Planning an Emergency Steering Drill

Risk Assessment

Identify hazards in steering gear room (oil leaks, noise, rotating machinery).

Ensure adequate lighting and PPE (ear protection, safety shoes, gloves).

Watch for trip hazards around hydraulic lines and motors.

Toolbox Meeting

Before the drill, brief the team:

Explain the scenario (e.g., autopilot failure during coastal passage).

Assign duties as per muster list.

Emphasise safety near moving machinery.

Review communication signals between bridge and steering gear room.

Step-by-Step Emergency Steering Drill Procedure

- Initiation of Drill

Master announces over PA: “Emergency Steering Drill in progress.”

General alarm may be sounded if required.

- Change from Automatic to Manual Steering

On the bridge, change over from autopilot to hand steering.

Test rudder movement with helm orders.

- Change from Bridge Control to Local/Emergency Control

Simulate failure of main steering control system.

Duty officer orders steering to be taken from local steering gear room.

- Activation of Local Steering Gear

Steering gear room team switches to local control (manual hydraulic levers).

Confirm rudder movement visually or on rudder angle indicator.

- Testing Emergency Communications

Communication between bridge and steering gear room must be tested:

Sound-powered telephone or

VHF/Walkie-talkie backup.

Bridge gives helm orders, steering gear room confirms and executes.

- Emergency Power Supply (if fitted)

Test operation of steering gear using emergency generator/alternative power supply.

- Completion of Drill

Return steering control back to bridge.

Master announces “Drill completed.”

Equipment reset and steering tested again in normal mode.

Duties During Emergency Steering Drills

Master

Has overall responsibility.

Monitors response time.

Conducts debrief.

Chief Officer

Coordinates the drill.

Supervises bridge team.

Ensures log entries and records.

Chief Engineer

Ensures steering gear room is manned safely.

Oversees testing of power supply and hydraulic pumps.

Duty Deck Officers

Give helm orders from bridge.

Record drill timings.

Maintain situational awareness during drill.

Steering Gear Room Team (Ratings/Cadets)

Operate local steering gear levers.

Report rudder movement back to bridge.

Observe safety precautions around machinery.

Common PSC & RightShip Observations

Crew not familiar with steering changeover procedures.

Emergency communication equipment (sound-powered phones) not working.

Local steering levers stiff or malfunctioning.

Emergency power supply not tested.

Logbook entries vague or missing.

No record of drill within the last three months.

Pro Tips for Effective Drills

Time the drill – inspectors may ask “How long did it take to switch to local steering?”

Rotate steering gear room teams each drill so everyone gets practice.

Practice in daylight and night conditions.

Test both steering pumps (No.1 and No.2) individually.

Train cadets on sound-powered telephone operation a common weak area.

After the drill, reset all systems properly and double-check rudder response.

Conclusion

Emergency steering drills are often overlooked until an inspector asks for a live demonstration. A well-prepared crew can switch from bridge control to local steering in under a minute proving both competence and compliance.

Whether you are a Master, officer, cadet, or rating, treat every emergency steering drill seriously. It might be the difference between a safe ship and a disaster during a real steering failure.

A ship is only as safe as its crew’s ability to steer it even in an emergency.

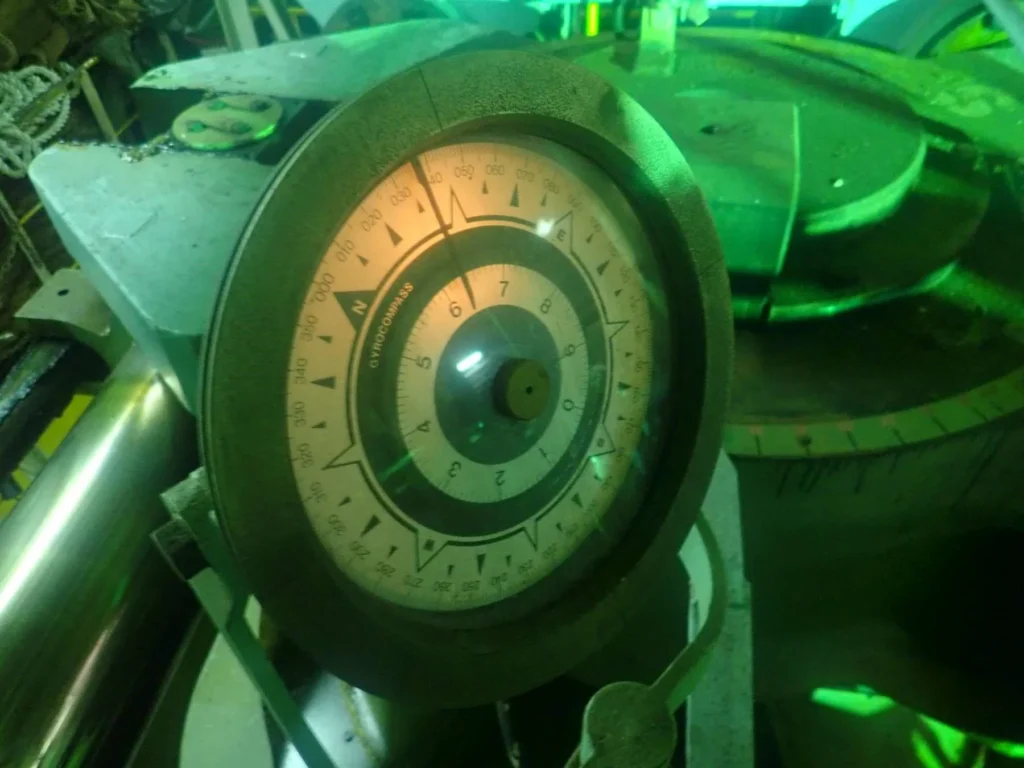

Below photos from actual onboard Emergency Steering Drill

Gyro repeater in steering gear cross checked with bridge

Steering engaged from local control and bridge orders followed

Verification of actual helm from steering gear room