Introduction

A Docking Plan is one of the most critical statutory drawings carried on board a ship. It provides detailed information about the underwater shape of the hull and specifies how the vessel should be supported when entering dry dock. Shipyards, classification societies, and ship officers rely on it to avoid structural stress or damage during docking operations.

Improper docking can cause serious accidents, such as hull deformation, cracking of bilge keels, or damage to the stern frame. For this reason, every ship must have a correct and updated docking plan approved by its classification society.

What Does a Docking Plan Show?

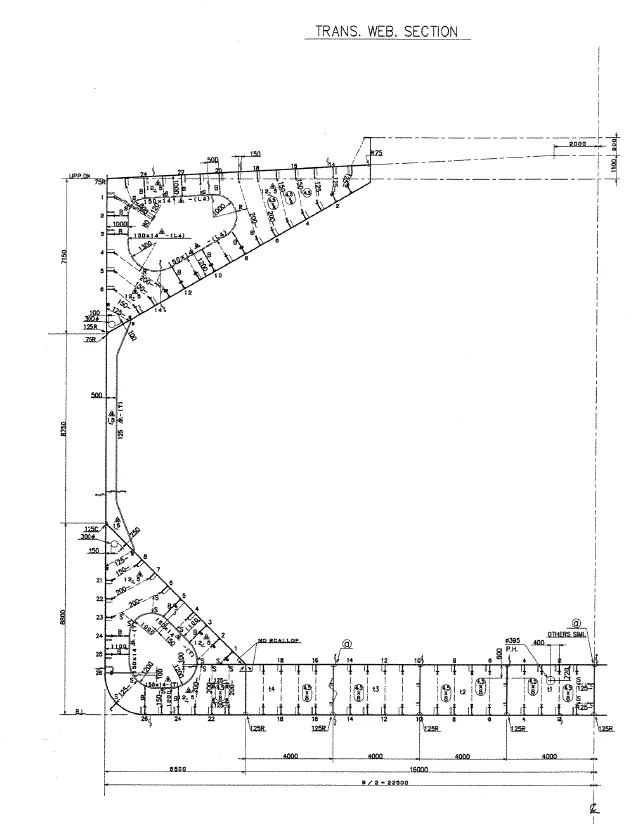

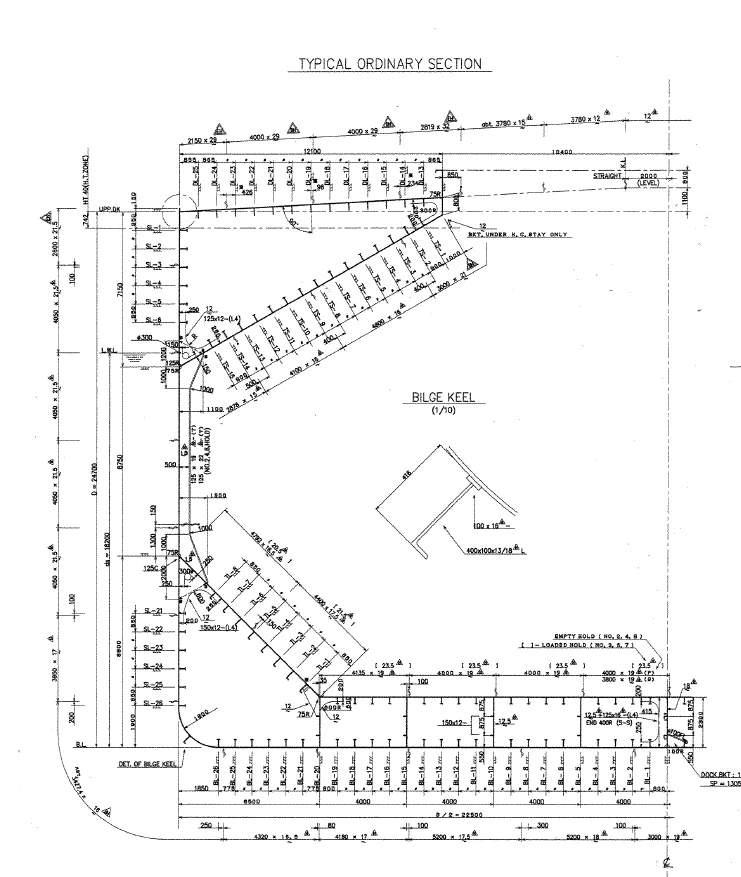

A typical docking plan consists of two main views of the vessel:

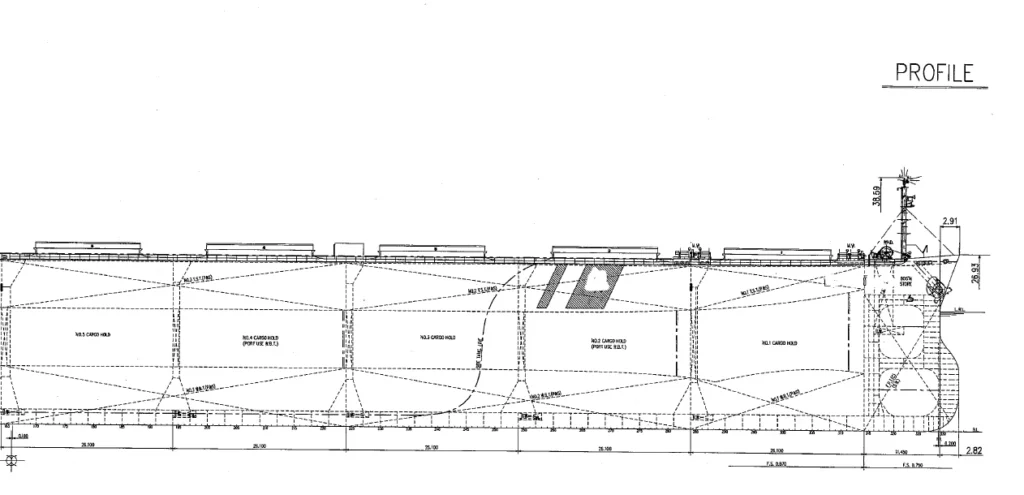

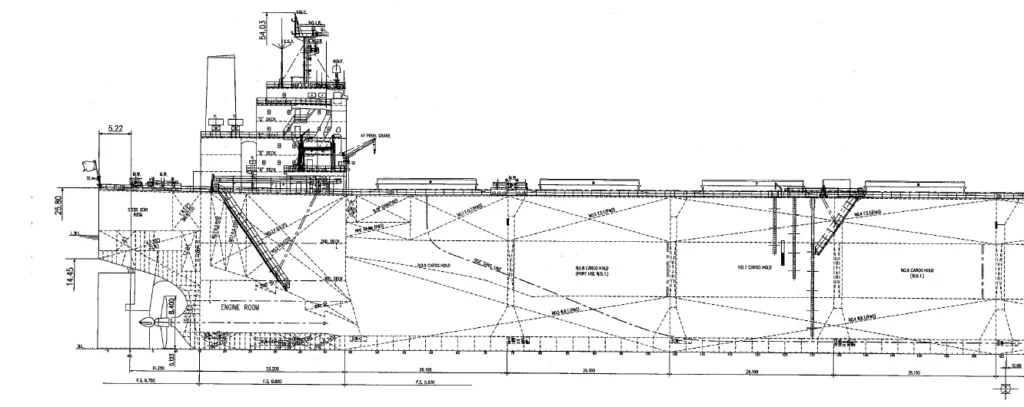

- Profile (Side View)

Shows keel line along ship’s length.

Frame numbers marked from forward to aft.

Appendages visible below the baseline (rudder, propeller, sonar domes, thrusters).

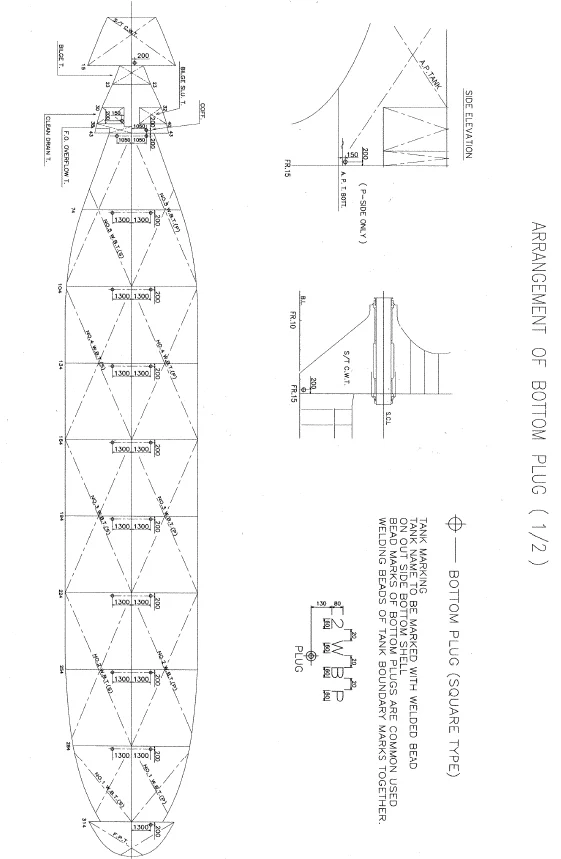

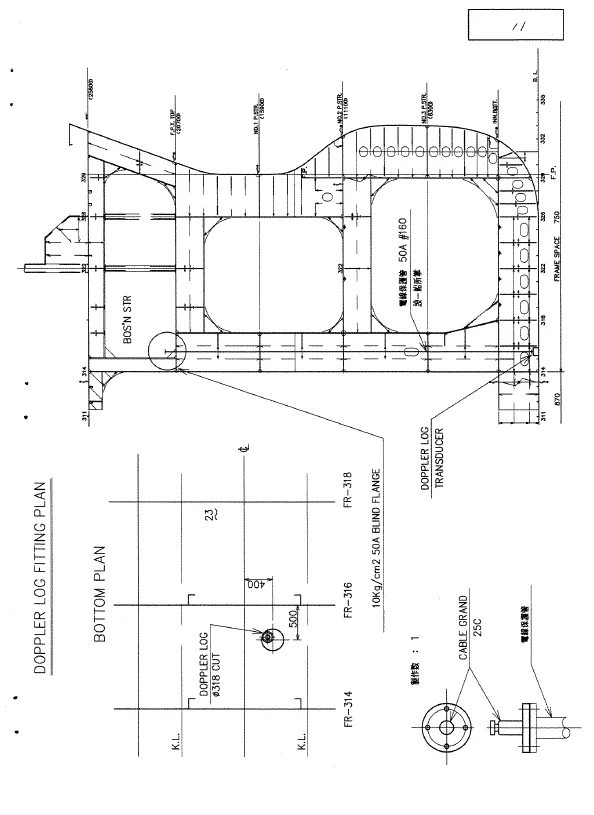

- Bottom View (Plan View)

Represents the ship’s underwater hull as seen from below.

Includes the keel block line along the centerline.

Shows bilge keel positions to avoid interference with bilge blocks.

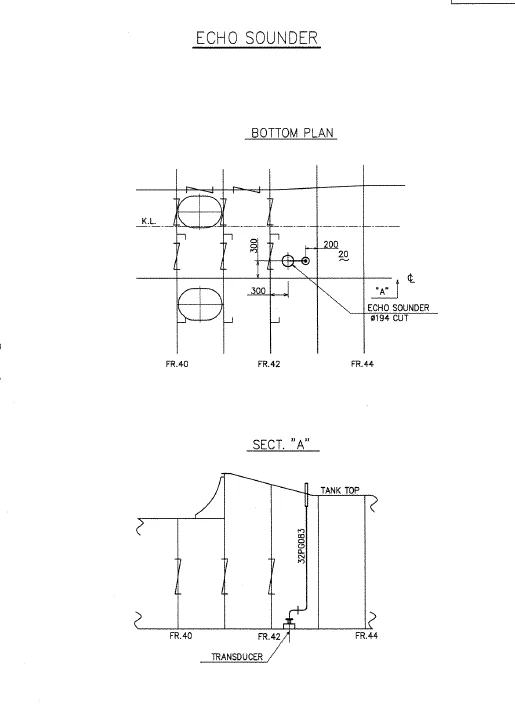

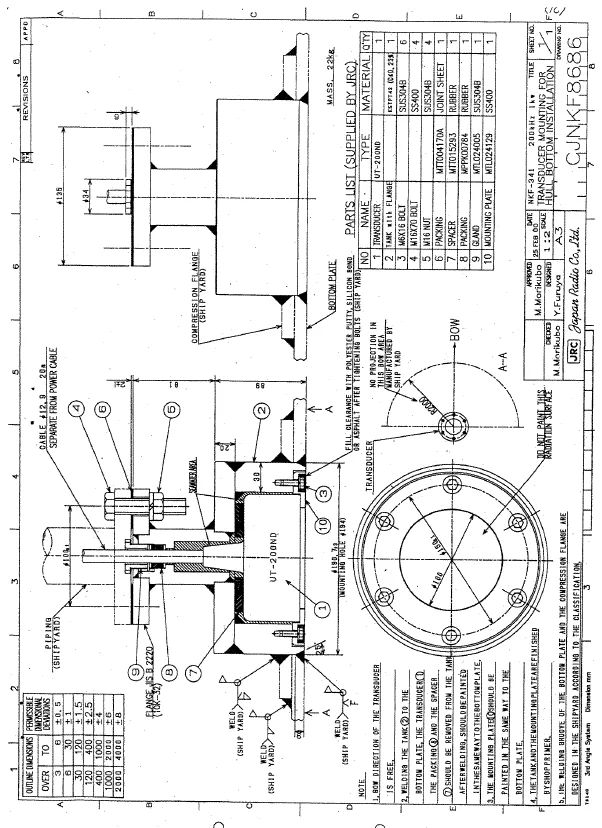

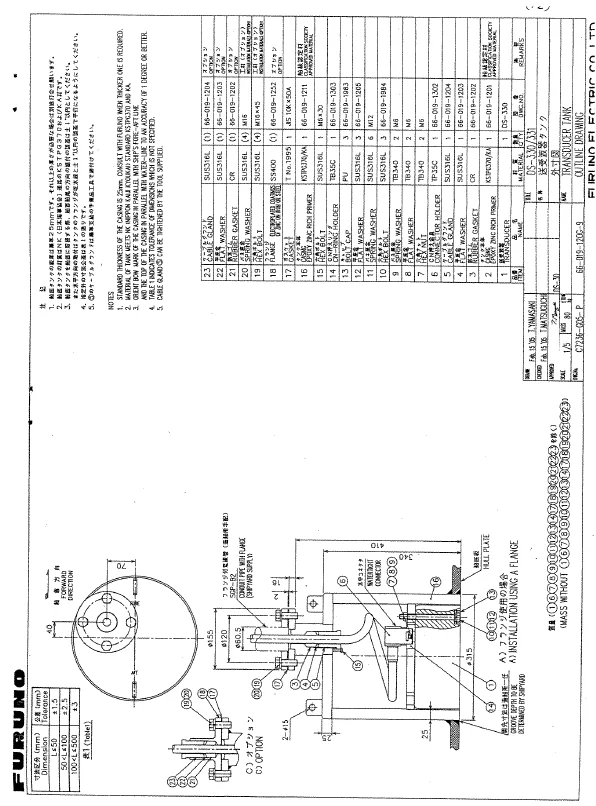

Marks sea chests, overboard discharge openings, ICCP anodes, echo sounder, speed log, stabilizer fins, etc.

Other information provided:

Keel block spacing and dimensions.

Bilge block positioning for stability.

Minimum clearance required under rudder, propeller, thrusters, and sonar domes.

Docking draft (required trim and draft for docking).

Light ship weight and displacement curve to assist dock master in block load calculations.

Purpose of Docking Plan

The docking plan serves four primary purposes:

- Safe Structural Support

Ships are designed to withstand loads when afloat, but not when supported on blocks. The docking plan ensures blocks are placed at strong structural members like the keel girder and transverse floors.

- Guidance to Dock Master

Docking masters use the plan to:

Align keel blocks with ship’s centerline.

Position bilge blocks away from appendages.

Adjust block height for required propeller and rudder clearance.

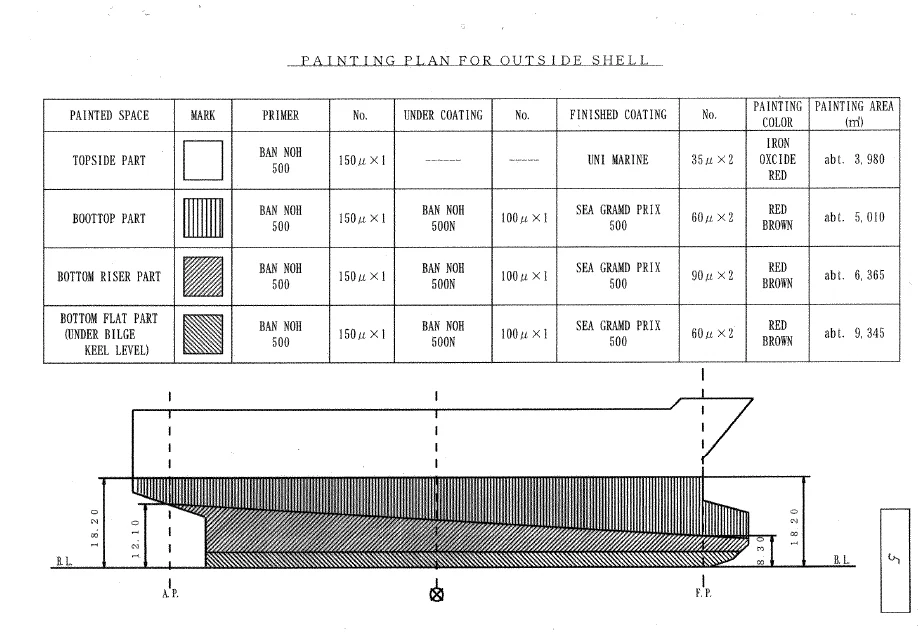

- Survey and Maintenance Work

The plan shows the location of sea chests, overboard discharges, ICCP anodes, echo sounders, and stabilizers, ensuring these areas remain accessible for inspection and maintenance.

- Emergency Docking

In case of grounding damage or hull failure, the docking plan helps dockyards decide where to support the vessel safely.

Docking Draft and Trim

The docking plan specifies a docking draft, which is the ideal draft at which the ship should enter the dock.

Usually, the ship is docked level keel, but sometimes a small trim by stern is advised.

The plan provides the critical draft beyond which appendages may touch blocks prematurely.

Example:

If a docking plan states Docking draft: 6.2 m even keel, the ship must be trimmed and ballasted to 6.2 m at the keel before entering dry dock.

Block Arrangements

- Keel Blocks

Form the main support line under the keel girder.

Typically spaced 0.8 – 1.2 m apart.

Height of blocks ensures adequate clearance under rudder and propeller.

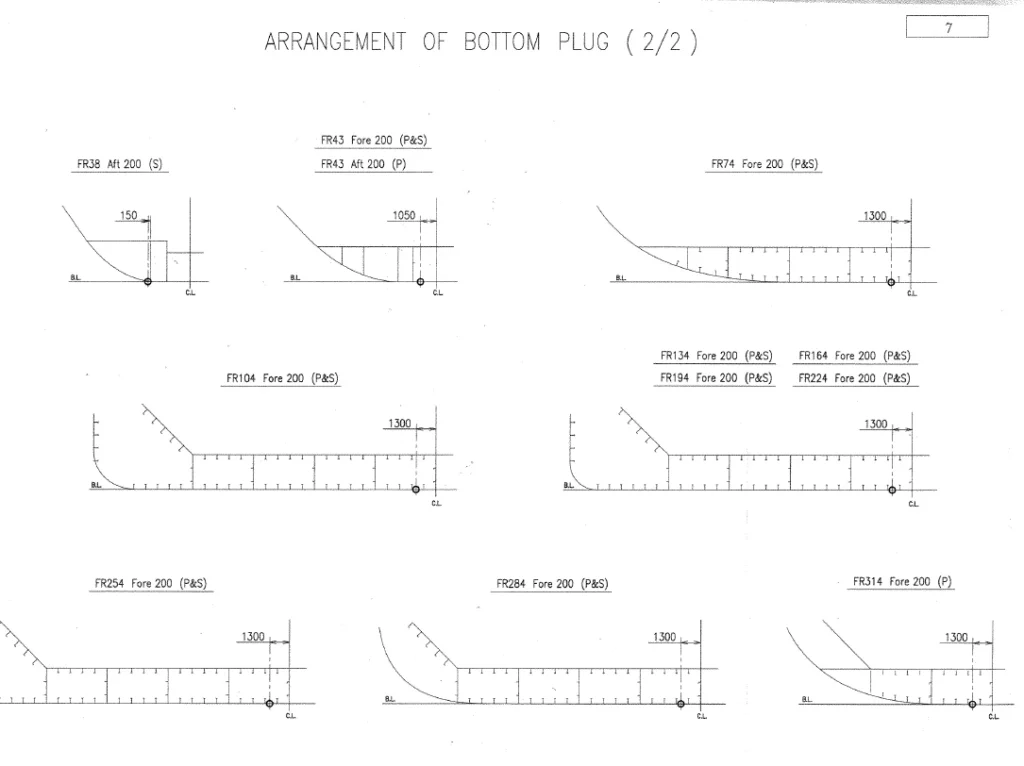

- Bilge Blocks

Provide lateral stability and prevent the ship from heeling.

Positioned against strong bilge strakes, never against bilge keels.

Raised only after the vessel is settled on keel blocks.

Officer’s Role During Dry Docking

Seafarers must actively participate in dry docking operations. Key responsibilities include:

- Pre-Docking Preparations

Verify docking plan onboard and discuss with dock master.

Ensure ballast condition matches required docking draft.

Confirm all overboard valves are shut and blanks fitted.

- During Docking

Officer monitors as water is pumped out.

Check that ship settles evenly on keel blocks.

Ensure bilge blocks are positioned only after keel is fully rested.

- After Docking

Cross-check rudder, propeller, and stern tube clearance.

Confirm sea chests, echo sounder, and log sensors are not obstructed.

Assist surveyors with UTM gauging and inspection work.

Typical Docking Accidents (Due to Wrong Plan Usage)

- Bilge keel damage: If bilge blocks press against bilge keel instead of bilge strake.

- Rudder jamming: Due to insufficient clearance under stern.

- Hull cracking: If keel block spacing is wrong, causing uneven stress.

- Sensor and anode damage: If appendage positions are not properly marked.

Difference Between Docking Plan and Other Plans

Docking Plan: For block positioning and docking operations.

Shell Expansion Plan: For hull plating arrangement and thickness.

General Arrangement Plan: For ship layout, decks, and spaces.

Capacity Plan: For tank volumes and cargo distribution.

Modern Developments

Use of 3D laser scanning to match actual hull shape with docking plan.

Digital docking plans integrated into ship management software.

Automated block arrangement software used by shipyards.

Pro Tips for Junior Officers

Carry a laminated docking plan to the dockside briefing.

Memorize rudder and propeller clearance values.

Never allow bilge blocks to be placed against bilge keels.

Always check the final resting position of the ship on blocks before signing dock master’s documents.

Cross-reference docking plan with stability booklet for light ship displacement and block loading.

Conclusion

The docking plan is not just a drawing it is the lifeline of safe dry docking. Every officer must understand its details, from keel block spacing to appendage clearances. A well-understood docking plan prevents accidents, saves time in dock, and ensures the ship’s structure is preserved.

Mastering this document is an essential skill for officers preparing for senior ranks and dry dock responsibilities.

References

International Maritime Organization (IMO), SOLAS 1974, as amended, Chapter II-1 (Construction Structure).

IACS, Recommendation No. 21 – Guidelines for Surveys in Dry Dock.

DNV, Rules for Classification of Ships

ABS, Guide for Dry Docking and Hull Surveys.

Lloyd’s Register, Hull Construction and Survey Guidelines