A chief engineer’s guide for junior engineers on a chemical tanker must emphasize rigorous safety management, practical risk assessment, and the disciplined use of personal protective equipment (PPE) during all operations. This approach not only meets regulatory compliance but also cultivates a safety-first culture that minimizes incidents and ensures everyone’s well-being onboard.

Safety Management & Risk Assessment

All tasks on chemical tankers, whether routine or unique, must start with risk awareness. The ISM Code requires identification and mitigation of risks to ships, personnel, and the environment. Risk management on board is not just about paperwork—it’s an active process that begins with hazard identification, understanding who may be harmed and how, evaluating and controlling risks, and continuously reviewing safety measures.

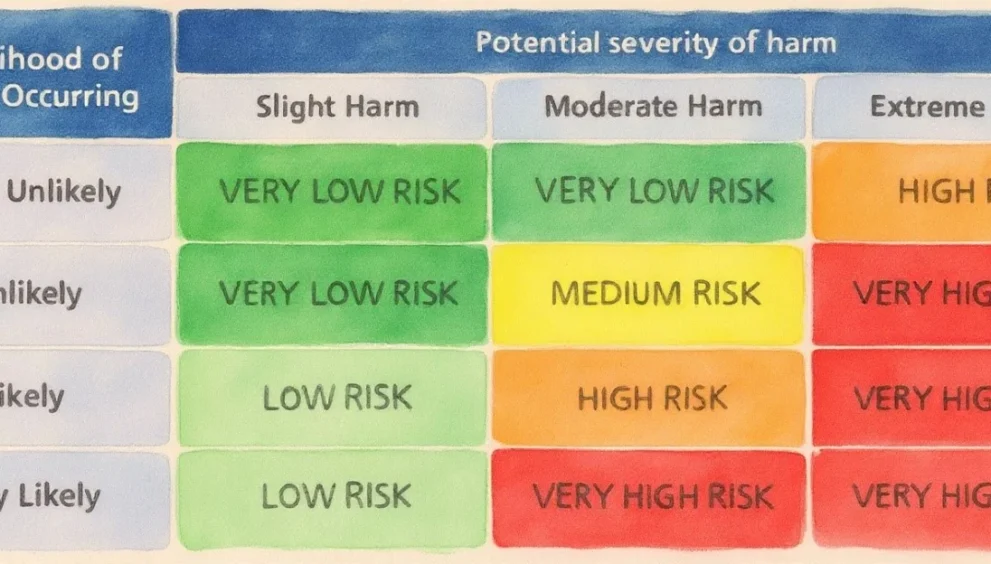

A formal risk assessment, including consultation with those carrying out the task, is mandatory for non-routine operations. This assessment should utilize a risk matrix, balancing the probability and severity of harm, and lead to practical controls or the decision not to proceed if risks cannot be sufficiently managed. Always keep assessments straightforward—overcomplication can hide real hazards.

Safe Operations: Routine and Non-Routine Tasks

Routine operations must have documented procedures as part of the Safety Management System (SMS). These procedures must be based on best practice, regularly audited for updates, and improved as required, with all hazards and safeguards clearly described. For non-routine operations—those not covered by existing procedures—a detailed risk assessment and shoreside approval are required before work begins.

Remember: never treat a procedure written for one task as a generic solution for others. Each unique operation must be carefully evaluated and separately approved.

Personal Protective Equipment (PPE) for Chemical Tankers

Atmosphere Monitoring Equipment

Atmosphere monitoring is essential due to the tendency of chemical vapors to accumulate in low areas and complex deck structures. Portable personal gas detectors should be worn by all crew on deck, and frequent sampling at different deck levels is necessary—especially when handling volatile cargo or during still weather. These practices help in early detection of toxic vapors or oxygen-deficient atmospheres, enhancing overall safety

Safe Working Clothing

Crew should wear overalls of cotton or non-static material, chemical-resistant safety shoes with steel toe caps, a safety helmet, working gloves, and goggles. High-visibility or self-reflecting patches on work gear are recommended. Clean, well-maintained working clothing reduces the risk of contamination and secondary health issues.

Protective Clothing

Protective clothing acts as a secondary barrier if containment systems fail. The selection and use must follow manufacturer guidelines and cargo MSDS recommendations. Properly maintained protective gear mitigates risks from accidental exposure to hazardous cargo

Toxic or Corrosive Substance Protection

When handling toxic or corrosive cargoes—such as during sampling, hose connection/disconnection, investigating leaks, or managing spills—adequate protective suits, gloves, and face protection are mandatory. Withdrawal and replacement of contaminated gear should follow every incident.

Chemical Resistant Clothing and Protective Suits

Chemical-resistant suits provide essential protection where there is a risk of exposure, such as at manifolds or during tank cleaning. Suits must be leak-proof, thoroughly cleaned after contamination, and stored according to manufacturer guidelines to maintain readiness and longevity.

Types of Chemical Resistant Clothing

The degree of protection depends on chemical, physical, and operational risk. International standards (EN, ISO, NFPA) categorize clothing (e.g., gas-tight, liquid-tight, spray-tight, partial protection). The protective suit’s material must be matched precisely to the hazard, referring to a chemical resistance compatibility list. Protection should be balanced to avoid undue physical stress or discomfort

Eye Protection

Due to the vulnerability of eyes to chemical injury, appropriate eye protectors must be chosen. Options include:

Safety goggles: Complete chemical and mechanical protection.

Face shields: Shield from splashes, worn with goggles.

Safety spectacles: Less suitable for chemicals, ideal for dust/chipping.

Selection must always match the specific chemical hazard.

Hand Protection

Gloves must be resistant to the chemical handled (nitrile, neoprene, PVC, or rubber based on MSDS guidance), and allow for sufficient manual dexterity. Long-cuff gloves extending over sleeves offer better protection; all gloves must be checked for deterioration and changed regularly.

Foot Protection

Rubber or PVC boots with reinforced toe caps are necessary during cargo operations or when physical or chemical exposure is likely. Boots should be cleaned after use and withdrawn if damaged or showing chemical degradation.

PPE Matrix

A PPE matrix details the minimum PPE required for various shipboard tasks; it should be referenced for every operation. The matrix takes into account different cargoes, operational risk, and required protection levels, ensuring that crew are never under-protected.

Respiratory Protection

Respiratory protection (facepiece with supplied fresh air) is needed any time toxic vapors or low oxygen are possible. Proper fit, compatibility with other PPE, and regular inspection are critical. Special policy applies to personnel with facial hair due to impact on facepiece seal.

Canister or Filter-Type Respirators

These respirators may only be used for dust maintenance tasks, never for vapor, toxic gases, or oxygen-deficient environments. Filter-type respirators cannot guarantee safety for cargo vapor mixtures, so must be strictly controlled and only permitted for non-cargo work.

Self-Contained Breathing Apparatus (SCBA)

SCBA delivers a finite supply of breathing air via a full face mask, protecting against vapors and lack of oxygen. The number of sets must comply with the IBC Code. SCBA must be stored outside risk areas, kept charged, and immediately accessible. Training and use limits apply.

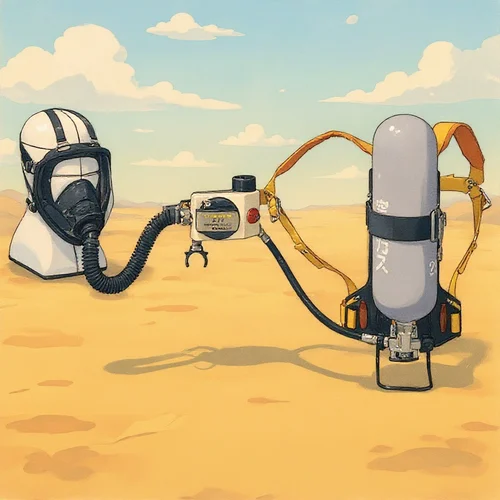

Air Line Breathing System

Such systems supply air from a remote source via a hose and belt connector. When used in enclosed spaces, an emergency short-duration SCBA must be provided in case of main air supply failure. Clean, filtered air is essential for safe use.

Emergency Escape Respiratory Protection

Ships must carry respiratory escape sets with 15-minute air capacity for every person, as mandated for certain chemical cargoes by the IBC Code. These are for escape only and must be strategically stowed for rapid access in emergencies

Maintenance

All PPE must be inspected (at least monthly for breathing apparatus), cleaned, and any defects corrected promptly. Inspection, maintenance, and repair records should be maintained. Spare parts must be stocked, and air cylinders promptly recharged after use.

Training

Practical, scenario-based training on all PPE types is mandatory. Only fully trained crew should operate specialized PPE, particularly breathing apparatus. Regular drills ensure crew confidence, capability, and ongoing familiarity with equipment and procedures.

All new junior engineers should treat every procedure and PPE checklist as a minimum standard to exceed, not simply meet. Safety and preparedness are values to be internalized—not items to be checked off. On this ship, proactive risk management and rigorous PPE discipline are what protect lives and reputations every day.