A fresh water generator (FWG) is one of the unsung yet essential machines onboard every vessel, converting seawater into fresh water for daily use. For cadets and junior engineers, mastering its operation is a key step toward safely sustaining crew life and honing engine room competency. The following blog, written from the perspective of a Chief Engineer and mentor, explores the core concepts, practical maintenance, and real-world importance of the FWG—directly relating these principles to onboard practices and career development in marine engineering.

The Fresh Water Generator: Lifeline at Sea

The fundamental function of a fresh water generator is to produce potable water by converting seawater, a continuous resource, into fresh water for drinking, cooking, washing, and supplying key machinery like boilers and cooling systems. Imagine your vessel spending weeks at sea; the FWG is what upholds comfort and safety in isolation.

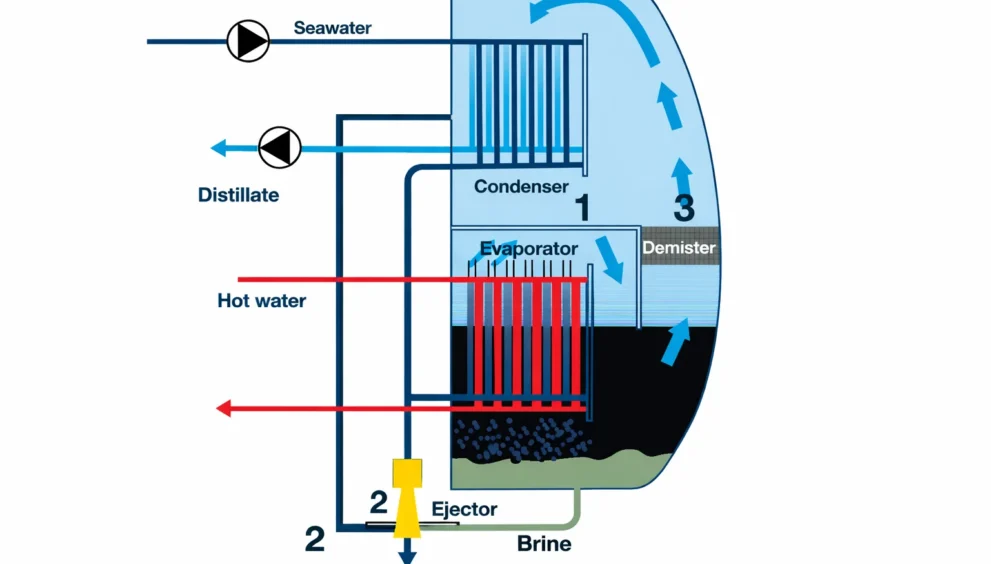

Onboard, FWGs typically operate via distillation, using engine jacket cooling water or steam to evaporate seawater under vacuum, then condensing it back to pure water—a neat process that leverages waste heat and minimizes power consumption.

Components and Working Principle

Key components every junior must know:

- Filter: Removes large particles from incoming seawater.

- Heat Exchanger (Evaporator/Condenser): Evaporates and recondenses water vapor using jacket cooling water.

- Salinometer: Monitors salt content, sounding an alarm if it exceeds safety limits, ensuring only pure water enters tanks.

- Demister: Removes water droplets from the vapor so only steam enters the condenser.

- Air/Brine Ejector: Creates vacuum and removes brine (concentrated saltwater) with air, maintaining optimal chamber conditions.

Operation steps:

- Pre-filtered seawater enters the evaporator, is heated by engine jacket water, and boils at a low temperature under vacuum.

- Steam rises, passes through the demister, and enters the condenser, where it’s cooled and collected.

- Salinometer and automatic control ensure only water below 15 ppm salt enters storage.

Practical Maintenance and Troubleshooting

As Chief Engineer, mentor juniors to focus on these practical areas:

- Inspection: Open the separator shell regularly to check for scale; a drop in production signals cleaning is due.

- Cleaning: Use mild acid solutions to descale heat exchanger plates, rinse completely, and inspect gasket integrity.

- Filter and Strainer Care: Clean intake filters and mesh screens to avoid blockages and loss of efficiency.

- Salinity Checks: Test salinometer alarms monthly to maintain water quality and prevent contamination.

- Pump & Valve Checks: Listen for abnormal noises, check for leaks, lubricate moving parts, and confirm proper operation of ejectors and pumps.

- Operational Caution: Always stop the FWG near ports or when passing through polluted waters to prevent system fouling.

These maintenance rituals not only safeguard machinery but instill discipline and technical skill in junior engineers.

Mentoring Cadets & Junior Engineers

Mentoring is about nurturing accountability, curiosity, and capability. Encourage juniors to:

- Take charge of simple FWG operations like starting, stopping, and logging parameters.

- Ask questions about each step—how does vacuum formation aid boiling? Why is scale harmful?

- Report promptly to seniors and never perform unsupervised operations.

- Practice resilience—maintenance may be challenging, but persistence ensures reliability for the whole crew.

mohit jangid

08th Jan 2026test

mohit jangid

08th Jan 2026testt