A screw compressor is an essential piece of machinery onboard ships, tasked with supplying compressed air for a wide range of vital operations—such as engine starting, control systems, and service air requirements. Marine screw compressors are favoured for their reliability, steady output, and efficiency, making them the industry standard for continuous duty air supply in maritime environments.

How Does a Marine Screw Compressor Work?

Marine screw compressors operate on a rotary principle, where intermeshing rotors compress air as it travels along the length of the screws. These compressors are typically oil-injected, meaning lubricant is introduced during the compression process to ensure cooling, sealing, and longevity of the components.

Key steps in their operation include:

- General Preparation: Before starting, all electrical connections and earthings must be thoroughly checked in compliance with local codes. The air outlet valve and condensate drain system must be carefully set up.

- Startup Sequence: After powering the compressor, the motor starts if the rotation direction is correct; otherwise, motor phase reversal may be needed. The air outlet valve must be opened, and the compressor should be run briefly to confirm normal operation.

- Continuous Running: For reliable performance and to avoid condensate in the oil, it is recommended to operate the compressor with a sufficient load factor above 10%.

- Stopping: The compressor should be unloaded before stopping. Emergency shutdown procedures should only be used in a fault situation.

Maintenance Best Practices

Effective maintenance ensures operational safety and long compressor life. Marine screw compressors must be maintained regularly according to the preventive schedule provided by the manufacturer.

Routine maintenance tasks include:

- Daily: Check oil levels and drain condensate from the receiver.

- Every 50 hours: Inspect belt tension and adjust as needed.

- Every 500–1,000 hours: Inspect and clean the air filter, check belt condition, inspect and clean cooling systems.

- Yearly or after 4,000 hours: Replace oil filter, air filter, and oil separator. Test safety valves and electrical components.

- 8,000 hours: Change the oil (using recommended lubricants), replace belts, clean inlet valves, and service instrument blocks.

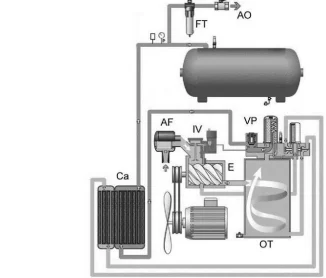

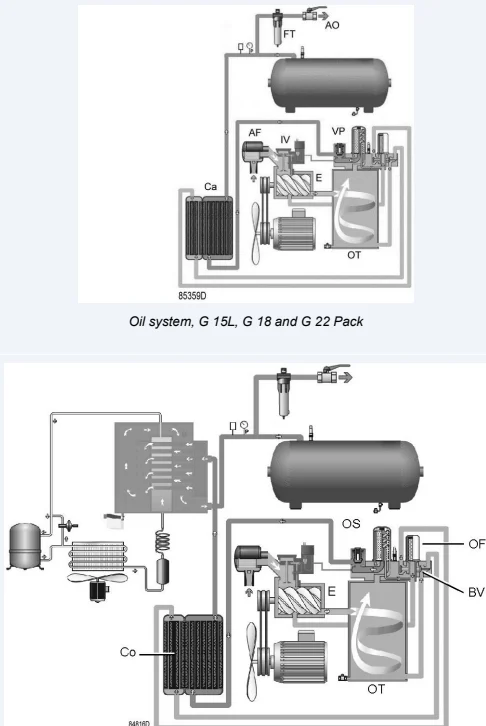

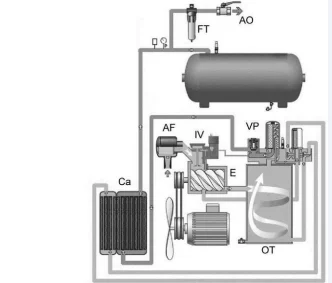

AIR FLOW

Air drawn through filter (AF) and open inlet valve (IV) into compressor element (E) is compressed. Compressed air and oil flow into oil separator/tank (OT). The air is discharged via minimum pressure valve (Vp), air cooler (Ca) and air dryer (DR) towards the air outlet (AO).

OIL SYSTEM

Air pressure in the oil separator tank (OT) forces the oil from the tank to compressor element (E) via oil cooler (Co) and oil filter (OF). Compressed air and oil flow into oil separator/tank (OT) where most of the oil is separated from the air by centrifugal action. The remaining oil is removed by oil separator (OS) and returns to the oil circuit via a separate line. The minimum pressure valve (Vp – see section Air flow) ensures a minimal pressure in the tank, required for oil circulation under all circumstances.

The oil system is fitted with a by-pass valve (BV). When the oil temperature is below the set-point of the valve, the by-pass valve shuts off the oil supply from oil cooler. The by-pass valve starts opening the supply from cooler (Co) when the oil temperature exceeds the setting of the valve. The setting of the by-pass valve depends on the model. See the section Compressor data.

COOLING SYSTEM

The cooling system of the Pack version comprises oil cooler (Co) and fan (FN). The fan, mounted directly onto the motor shaft, generates the cooling air in order to cool the oil and the internal parts of the compressor.

Always use authorized spare parts to keep warranties valid, and avoid mixing oils from different brands to maintain oil quality and system reliability. Extra care is needed if operating conditions are harsh, such as high ambient temperatures or environments with high humidity and dust.

Conclusion

- Before undertaking any operation or maintenance, always consult the official instruction manual and follow all safety precautions meticulously.

- Regular checks and preventive maintenance are key to efficient and safe compressor operation at sea.

- Understanding manufacturer guidance on oil and filter change intervals is essential, especially in extreme or polluted environments.

Marine screw compressors represent advanced technology and require systematic management for optimal performance. Developing practical skills in their operation and care will be invaluable for a career at sea.