Onboard an LPG carrier, one of the most vital pieces of equipment in the cargo handling system is the deepwell cargo pump. For a junior engineer joining the vessel, it is important to understand not just what the pump does, but also why it is fitted, and how it works.

Purpose of a Deepwell Cargo Pump

The LPG cargo deepwell (DW) pump is essentially our lifeline for loading and discharging cargo. Its main function is to safely and efficiently transfer cargo from the storage tanks to the shore during discharges, or between tanks in case of onboard operations such as stripping or gas freeing.

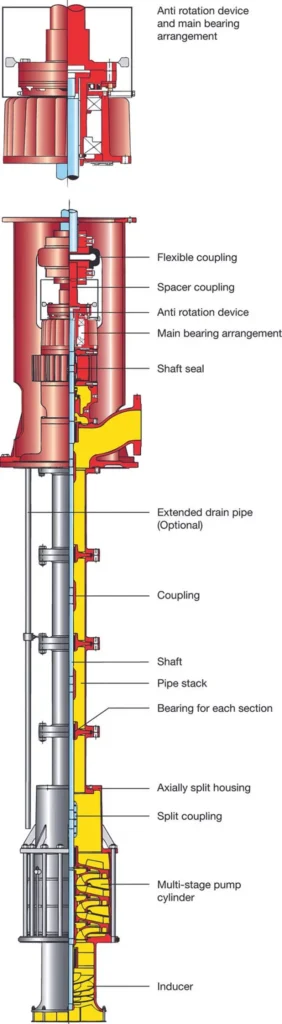

Unlike general centrifugal pumps used in engine rooms, the cargo DW pump is specifically designed to operate directly inside the cargo tank. This arrangement eliminates the need for large cargo pipelines running out of the tank bottom and reduces risks of leakage. It also ensures we can discharge cargo fully, down to the stripping level.

In simple terms: without functioning cargo deepwell pumps, the ship cannot trade.

Working Principle

The DW pump onboard our LPG carrier is a centrifugal type pump. This means the flow it delivers depends on the discharge pressure (back-pressure). A key thing to remember:

- If discharge back-pressure increases, pump capacity decreases.

- Power consumption also reduces with increasing back-pressure, because the load on the pump is more dependent on flow than pressure.

The pump creates a pressure rise, or pressure head, which is essentially the difference between suction pressure (from the cargo level inside the tank) and discharge pressure (towards ship/shore line).

To give you a practical relationship: the supplier usually provides pump performance data in terms of meters of liquid column (mLC), which is independent of cargo density. To convert that to bar, we use:

What this means for operation is that as the cargo level drops in the tank during discharge, the suction pressure decreases. To maintain proper flow, we need to carefully adjust the discharge valve, gradually opening it as the tank empties.

Operational Key Points for Juniors

- Cargo lubricated bearings – The pump bearings and wear rings are cooled and lubricated by the very cargo being pumped. Therefore, the pump should never be run dry for more than 5 seconds.

- Boiling point cargoes – LPG is always at its boiling point. Towards the end of discharge, there is a risk of cavitation at the suction side. This can be delayed by throttling the discharge valve to increase back-pressure and stabilize flow.

- Cavitation indicators – When cavitation occurs, flow breaks down and power consumption drops. The pump is protected by an electronic current relay, which trips at a minimum current setting (usually around 150A).

- Stripping operations – Sometimes, the low-ampere cutout may need to be bypassed manually to strip the last liquid from the tank. This must be done with extreme caution and for a very short time only.

Electric Motor & Restarting

Each DW pump is driven by its own electric motor mounted above the tank dome. The motor has strict limitations on consecutive starts:

- From cold: 3 consecutive starts allowed

- From warm: 2 consecutive starts allowed

After that, a one-hour resting period is required before attempting a new start.

This limitation protects the pump motor from overheating and must be respected at all times.

Maintenance Notes

Routine checks include monitoring the oil level in the seal system pressure vessel. Any signs of leakage must be investigated—usually it indicates a worn mechanical seal that requires maintenance. Always follow the maker’s instructions for refilling or replacing seals.

Final Advice to Juniors

Understanding the deepwell pump is not just about memorizing figures and procedures. Think practically: the pump’s health directly defines the vessel’s earning capacity. Respect its limitations, monitor closely during cargo operations, and develop the habit of listening to the pump. A change in vibration, motor load, or discharge pressure often gives the first clue of a developing issue.

When you stand watch during cargo, treat the pump as your responsibility. That’s what builds the confidence and trust of a competent marine engineer.