A step-by-step guide on rudder clearance measurement. Learn drop, pintle, stock, and carrier bearing clearances with survey methods and class limits.

Rudder Clearance Measurement – Complete Guide for Cadets and Junior Officers

Why Rudder Clearance Matters

The rudder is a vital part of the steering gear system, transmitting helm orders into ship movement. Because it operates under huge hydrodynamic forces, it depends on well-maintained bearings and pintles.

If clearances are outside class limits, risks include:

- Steering failure due to bearing wear.

- Vibration & noise affecting navigation.

- Loss of rudder control in heavy weather or restricted waters.

- Damage to stock, pintle, or hull structure, requiring costly repairs.

That’s why rudder clearances are always measured during dry dock surveys, class inspections, and sometimes after grounding incidents.

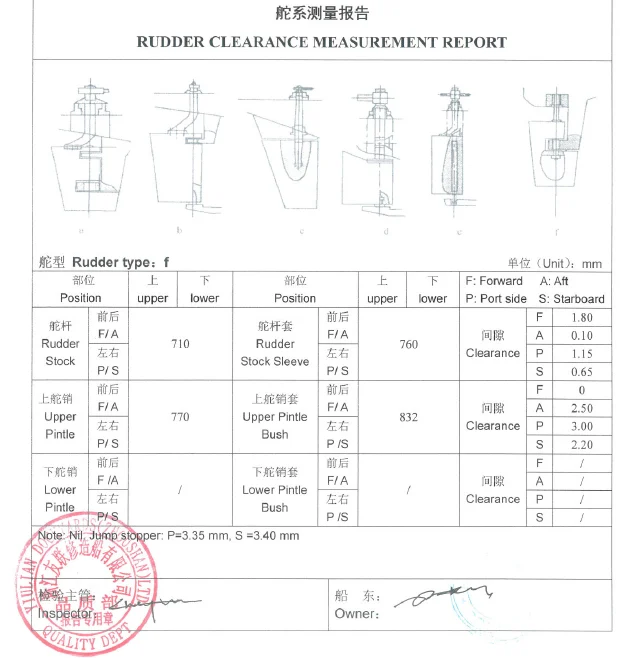

Clearances Checked in Rudder Surveys

Surveyors and shipyard engineers measure four key clearances:

- Rudder Drop (Vertical Clearance)

Movement of rudder downwards due to wear of lower pintle bearing.

Increase in drop = bearing wear.

- Pintle Bearing Clearance (Horizontal Clearance)

Side play between pintle and bearing.

Excess play = risk of vibration and uneven loading.

- Rudder Stock Clearance (Bush Clearance)

Gap between rudder stock and bush inside rudder trunk.

Excess clearance = bush wear → requires renewal.

- Carrier Bearing Clearance

Gap between rudder carrier bearing (takes vertical load) and stock collar.

Excess clearance = uneven load distribution → may damage bearing.

Methods of Measuring Rudder Clearances

- Rudder Drop (Vertical Clearance)

Tools: Dial gauge (0.01 mm accuracy), hydraulic jack.

Method:

- Dial gauge fixed at the bottom of rudder or at carrier bearing.

- Rudder slightly lifted with jack from carrier bearing.

- Gauge reading = drop value.

Typical Allowable:

For most class societies → 6–10 mm maximum (check vessel-specific rules).

If greater → lower bearing/pintle likely worn.

- Pintle Bearing Clearance (Horizontal Play)

Tools: Dial gauge.

Method:

- Gauge fixed on hull near pintle.

- Rudder moved sideways by steering gear or chain block.

- Gauge reading shows side play.

Typical Allowable:

Should not exceed 2–3% of bearing dia

A step-by-step guide on rudder clearance measurement. Learn drop, pintle, stock, and carrier bearing clearances with survey methods and class limits.

3. Rudder Stock Clearance (Bush Clearance)

Tools: Feeler gauge, wedge, or dial gauge.

Method:

1. Measure radial clearance between stock and bush inside trunk.

2. Taken at multiple points around circumference.

Typical Allowable:

Around 4–6 mm depending on class & stock size.

4. Carrier Bearing Clearance

Tools: Dial gauge or feeler gauge.

Method:

1. Jack up rudder stock slightly.

2. Measure gap between carrier bearing and collar.

Typical Allowable:

Should not exceed 1–2 mm.

Class Society Guidelines

Each classification society (ABS, DNV, LR, ClassNK, BV) gives detailed limits. General rules:

Rudder Drop: Not more than 6 mm increase from original/new value.

Pintle Clearance: Not more than 6% of pintle diameter.

Stock Clearance: Not more than 1.5–2.0 mm per 100 mm of stock diameter.

Carrier Bearing: Not more than 2 mm.

Always refer to the vessel’s approved docking manual and class surveyor instructions, as actual limits depend on rudder design and class rules.

Recording and Reporting

Measurements should be recorded in dry dock report and compared with previous docking values.

If any value exceeds limits, class surveyor may order:

Renewal of bushes/bearings.

Machining of pintle or stock.

Complete rudder removal and overhauling.

Common Findings During Docking

Excess drop: Lower pintle bearing worn.

Excess pintle clearance: Bush worn or pintle surface damage.

Uneven stock clearance: Misalignment or oval wear.

Carrier bearing play: Collar wear or insufficient lubrication.

Pro Tips

- Always zero the dial gauge before taking readings.

- Take measurements at several angular positions to detect oval wear.

- Record temperature conditions — expansion may affect readings.

- Don’t forget to lubricate pintle bearings after measurement.

- Keep at least 2 docking records for trend analysis — if wear is accelerating, plan repairs early.

Conclusion

Rudder clearance measurement may seem like a job for shipyard surveyors, but as a cadet or junior officer, knowing the types, methods, and limits helps you understand how your ship’s steering system stays safe.

The rudder is your ship’s “steering heart.” If its clearances are out of limit, even the best bridge team cannot keep the vessel safe. Learn this well, and you’ll always stand out during dry dock surveys and inspections.