If you’ve spent any time in the engine room, you know bilge water is just part of the job. It builds up over time a messy mix of oil, water, fuel, grease, cleaning chemicals basically everything that leaks or spills from machinery. And no, you can’t just pump it into the ocean. That’s illegal, full stop.

That’s where the OWS comes in. This system is not just another piece of equipment. It’s what keeps your ship legal, your record clean, and the marine environment safe.

Let’s walk through what it does, how it’s built, and how it works without overcomplicating things.

So, Why Do We Even Need an OWS?

Every ship creates oily bilge water. And you’re not allowed to dump it overboard unless the oil content is less than 15 parts per million (ppm) that’s the rule under MARPOL Annex I.

If you break that rule, the consequences can be serious heavy fines, vessel detention, or worse. So, the OWS is there to make sure only clean water goes overboard. Everything else gets dealt with properly.

What’s Inside an OWS?

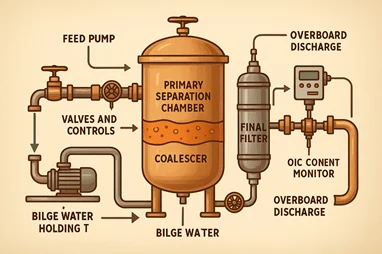

Think of the OWS as a multi-stage filter that kicks out the oil and lets the clean water go. It usually has these parts:

1. Feed Pump

Starts it all off. This pump pulls oily water from the bilge holding tank and pushes it into the separator. It needs to be reliable and handle thick, dirty water without issues.

2. Primary Separation Chamber

Here, oil and water start to split up. Oil is lighter, so it floats up. This stage takes care of the bigger oil droplets they rise to the top and are skimmed off.

3. Coalescer

This is where the magic happens. The coalescer helps small oil droplets stick together to form bigger ones. That makes them easier to remove. Without this stage, you’d never hit that 15-ppm limit.

4. Final Filter or Polisher

Some systems throw in an extra filter at the end, just to be safe. It’s like giving the water one last scrub before sending it overboard.

5. Oil Content Monitor (OCM)

This is the watchdog. It checks the water before discharge. If the oil level is under 15 ppm, it allows it to go out. If not, it shuts the valve and sends the water back to the bilge tank.

6. Valves and Controls

These helps manage flow and automatically respond if something’s off like if oil content suddenly spikes. They can trigger alarms, shut things down, or redirect the flow.

How Does the Whole System Work?

Here’s how it usually goes, step by step:

- Bilge water builds up in your holding tank.

- Feed pump sends it to the OWS.

- First chamber removes the bigger oil.

- Water goes through the coalescer to clean out the smaller oil droplets.

- Oil content monitor checks if it’s clean enough.

- If yes → overboard.

If no → it goes back to the bilge tank. - Everything gets logged. Alarms go off if something’s wrong. It’s all automatic.

What Are the Rules?

Here are the basics you cannot ignore:

- Ships over 400 GT must have a certified OWS.

- Oil in discharged water must be under 15 ppm.

- Every discharge has to be recorded in the Oil Record Book.

- The OCM needs yearly calibration and must be tamper-proof.

- Bypassing the system serious trouble. Don’t even think about it.

Common Issues You’ll Face

Even the best OWS can mess up if it’s not maintained. Here’s what usually goes wrong:

- Too much detergent in bilge water? You’ll get emulsions oil and water mixing too tightly. Hard to separate.

- Dirty coalescer It won’t do its job.

- Faulty OCM sensor Bad readings. Bad decisions.

- Wrong flow rate System can’t handle it.

- Untrained crew running it alone at night or in port Big risk.

Tip: Don’t just set it and forget it. Watch the gauges. Check the filters. Clean the unit regularly. And if there’s an alarm, don’t ignore it.

Final Thoughts

Look, it’s easy to see the OWS as “just another machine” in the engine room. But the truth is it’s a system that can make or break your compliance.

One bad decision, one wrong setting, or one skipped entry in the logbook and you could be dealing with fines, detentions, or even a court case.

So, here’s what you need to do:

- Understand how your OWS works.

- Maintain it regularly.

- Don’t bypass it ever.

- Keep your logs clear and honest.

- Train your juniors. Supervise operations.

Respect the alarms. They’re not suggestions.