When your OWS fails, it’s not just a technical issue. It can be a career-ending one.

Let’s not sugar coat it oily water discharge violations don’t just mean fines or a slap on the wrist. They can lead to detentions, serious investigations, losing your license, or worse.

So, instead of waiting for alarms, PSC visits, or things to go sideways, here are seven honest, practical tips that can keep your oily water separator running smoothly and keep you out of hot water.

1. Know What You’re Working With

Not every OWS is built the same. Some are basic setups with gravity separation and coalescers. Others come with filters, dosing systems, or smart automation.

Why does this matter? Because if you clean or operate it the wrong way, you could damage it or even break it completely.

What should you do?

- Take the time to read the manual. Yes, the actual one.

- Don’t just copy what the last engineer did. Systems vary.

- Learn how your specific unit works, from inlet to overboard.

2. Keep the Coalescer Clean. It’s the Heart of the System.

Think of the coalescer like a coffee filter. If it’s clogged or damaged, nothing works right.

What happens if you ignore it?

- Separation becomes poor and oily water might slip through.

- The OCM starts giving false alarms.

- You could cross the 15-ppm limit without even knowing.

What’s the right move?

- Stick to a cleaning schedule. Don’t wait for something to break.

- Use soft brushes and fresh water. No high-pressure blasting.

- Replace it if you see swelling, cracks, or general wear.

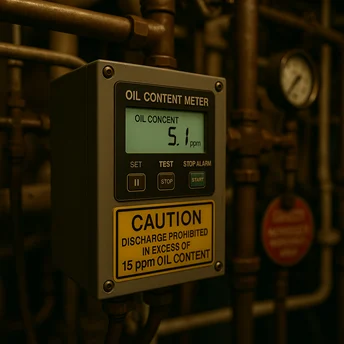

3. Watch the Oil Content Meter (OCM) Like a Hawk

Your OCM sees everything. It monitors every drop and records it. If it picks up a high reading, you can’t just ignore it.

What does it do?

- It checks the oil content in the discharge.

- If it goes above 15 ppm, it triggers an alarm.

- It logs the data so whatever it records must match the ORB.

How do you take care of it?

- Gently clean the lenses. Dirt affects accuracy.

- Calibrate it according to class or maker’s instructions.

- Test the alarm and auto-stop regularly. Make sure they actually work.

4. Test the Auto-Stop System. Do It Monthly. No Excuses.

If oil content spikes, the OWS should stop pumping right away. This is your final safety net before trouble starts.

What should you do?

- Simulate a high oil reading and check if the discharge stops.

- If it doesn’t work, fix it immediately. Not next week.

- Log the test in the PMS or engine room logbook.

Why is this important?

During inspections, this is one of the first things authorities will check. If it fails, you’re going to have a tough conversation.

5. Don’t Forget the Pipes. Backpressure Can Wreck the System.

We tend to focus on the separator itself and ignore the pipes and valves. But those can be the source of big problems.

What can go wrong?

- If the overboard valve is shut, pressure builds up.

- Dirty or narrowed pipes slow down flow, triggering alarms.

- The bilge tank might even overflow if the discharge gets blocked.

What’s your best move?

- Clean the discharge lines as part of your routine.

- Always check the overboard valve is open before running the OWS.

- Install pressure gauges if you don’t have them. They’re simple but very helpful.

6. Log Everything. No Shortcuts.

The Oil Record Book isn’t just paperwork. It’s your legal defence. If something goes wrong, the ORB is the first-place investigators will look.

What do you need to log?

- Date and time of discharge

- Total quantity processed

- Start and stop times

- Any maintenance, alarms, or OWS issues

Here’s a tip: Never write entries later. Don’t “fill in the blanks” from memory. And absolutely never copy someone else’s logs. What’s written in the ORB must match the OCM memory exactly.

7. Train the Juniors. Don’t Leave Them Guessing.

Let’s be honest. OWS operations often happen during night watches, port stays, or quiet hours. That’s when juniors are usually in charge.

So, what can you do?

- Show them how the system works, step by step.

- Help them understand why we care about that 15-ppm limit.

- Teach them what can go wrong—and how to react when it does.

Why it matters: If your juniors know what they’re doing, you’ll have fewer surprises and a safer engine room overall.

Your OWS Quick-Check Cheat Sheet

Before you say “All good,” ask yourself:

- Is the coalescer clean and undamaged?

- Is the OCM clean, calibrated, and working properly?

- Have you tested the auto-stop system this month?

- Are the overboard valves open and verified?

- Are discharge lines clear and free of blockage?

- Is your ORB accurate, honest, and up to date?

- Are your junior engineers trained and confident with the system?

Final Thoughts: Respect the OWS

It might not be the most exciting part of the engine room, but your oily water separator is one of the most closely watched systems on board.

Treat it right. A few extra minutes spent checking, cleaning, and logging could save you a world of trouble.

At the end of the day, being professional isn’t about avoiding blame it’s about doing the right thing, even when no one’s looking.